Engineering > QUESTIONS & ANSWERS > NACE 1 Questions and Answers 100% Pass (All)

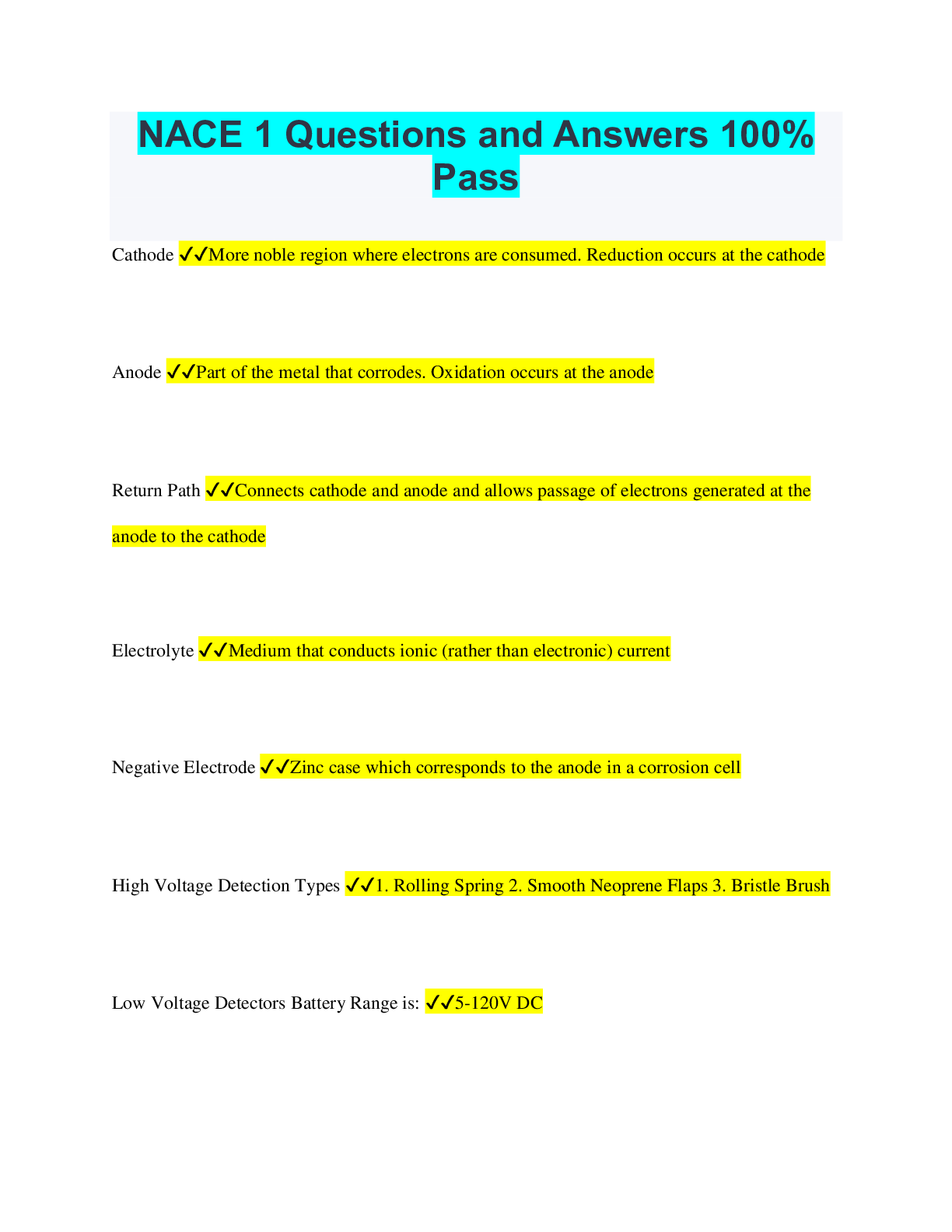

NACE 1 Questions and Answers 100% Pass

Document Content and Description Below

NACE 1 Questions and Answers 100% Pass Cathode ✔✔More noble region where electrons are consumed. Reduction occurs at the cathode Anode ✔✔Part of the metal that corrodes. Oxidation occurs at ... the anode Return Path ✔✔Connects cathode and anode and allows passage of electrons generated at the anode to the cathode Electrolyte ✔✔Medium that conducts ionic (rather than electronic) current Negative Electrode ✔✔Zinc case which corresponds to the anode in a corrosion cell High Voltage Detection Types ✔✔1. Rolling Spring 2. Smooth Neoprene Flaps 3. Bristle Brush Low Voltage Detectors Battery Range is: ✔✔5-120V DC General Types of Holiday Detectors ✔✔1. Low voltage DC 2. High voltage DC 3. High voltage pulsed DC 4. High voltage AC Adhesion Failures May be Caused by: ✔✔1. Contaminated surface 2. Wrong surface prep. 3. Insufficient profile 4. Exceeding topcoat window Checking can be Described as: ✔✔Line cracks in the coating surface Causes of Cracking ✔✔1. Stress from movement 2. Internal stress as coating ages Common Cause of Blistering ✔✔Surface contaminants: oil, moisture, and/or grease Pinholes are: ✔✔Small holes in the coating Vacoules or voids are typically caused by: ✔✔Air trapped in coating during mixing Cratering may be caused by: ✔✔Air trapped in coating A powdery, friable layer on the surface of a coating common with epoxy coatings is: ✔✔Chalking Runs, sags and wrinkles are caused by: ✔✔1. Coating applied too thickly 2. Too much thinner 3. Surface too hot 4. Improper spray technique Problems caused by amine blush ✔✔1. Surface tackiness 2. Incomplete cure 3. Poor adhesion Non drying films may be caused by: ✔✔1. Environmental issues 2. Wrong/contaminated thinner 3. Manufacturer coating issues MSDS contains following ✔✔1. Stability and reactivity 2. Handling and storage 3. PPE 4. Physical and chemical properties Coating product data sheets contain ✔✔1. Generic type 2. Description 3. Features 4. Color 5. Finish 6. Proper use 7. Performance data 8. VOC values 9. Application methods 3 ways coating is applied ✔✔1. Brush 2. Roller 3. Spray High temp concerns ✔✔1. Slow solvent evaporation 2. leaves moisture on coating surface Low temp concerns ✔✔1. Slow cure times 2. Increased viscosity Guide to enclosures ✔✔SSPC Technical Update #6 Project inspection documentation provides ✔✔1. QC records 2. Management Information 3. Verification of work 4. Details of non-conformance work Good records allow management to: ✔✔1. Detect design defects 2. Evacuate coating performance 3. Develop ongoing maintenance program 4. Determine annual cost data Inspection records show: ✔✔1. Environmental conditions 2. pretreatment details 3. Cleaning details 4. Materials information 5. Coating applications 6. Tests results Documentation may include ✔✔1. Dail reports 2. Inspection logs 3. Routine reports 4. Monthly/quarterly reports People who may be required to attend ✔✔1. Owner 2. Engineer 3. Ops personnel 4. Specifier 5. Purchase agent 6. Coating manufacturer 7. Coating inspector 8. Project safety 9. Coating applicator Goals of a pre-job conference ✔✔1. HSE discussion 2. Adress/clarify emergency procedures 3. Review SOW 4. Review logistical support 5. Discuss/clarify inspector responsibilities 6. Clarify chain of command Common errors using replica tape ✔✔1. Variation in point to point profile 2. Dirt on tape/guage 3. Guage accuracy 4. Rubbing technique Standards for replica tape ✔✔1. RP-0287-95-Accuracy 2. ASTM 4417-93-Reproducibility 2 types of replica tape ✔✔Coarse and extra coarse Iso comparator grades may by recorded as: ✔✔1. Finer than fine 2. Fine 3. Medium 4. Coarse 5. Coarser than coarse Depth of profile can be evaluated by: ✔✔1. Iso comparators 2. Replica tape 3. Digital profile guage Tests for soluble salts include: ✔✔1. Potassium Ferricynide 2. Bresle patch 3. Sleeve test 4. Conductivity 5. Soluble salt meters Effective inspection spec. for soluble salts should include: ✔✔1. Limits of salts acceptable 2. Specific salts limited 3. Test method 4. Frequency of testing 5. Where to administer tests 3 types of soluble salt contamination are: ✔✔1. Chlorides 2. Sulphates 3. Nitrates 3 surface profile test methods ✔✔1. Comparator and coupons 2. Replica tape 3. Profilometer NACE SSPC Waterjetting Standard ✔✔NACE 5/SSPC-SP12 3 types of water blasting ✔✔1. Grit blasting w/shroud 2. Sand injected water blast 3. Slurry blast w/grit & water mix Ulta high pressure water jetting range ✔✔30K to 50K PSI High pressure water jetting range ✔✔10K to 30K PSI High pressure water cleaning range ✔✔5K-10K PSI Low pressure water cleaning range ✔✔Below 5K PSI Recyclable grit types ✔✔1. Steel grit 2. Cast iron 3. Plastic beads 4. Sponge particles Abrasive media types ✔✔1. Shot grit 2. Crushed slag 3. Ceramic grit 4. Silica sand Checklist items for surface prep. ✔✔1. Ambient conditions 2. Substrate conditions 3.Pre-blast surface cleanliness 4. Shot/grit size 5. Shot/grit cleanliness 6. Surface profile 7. Operator qualification Describe low voltage holiday detectors ✔✔Sensitive electronic devices powered by batteries ranging from 5-120V DC 4 Typical SSPC-SP1 pre-cleaning methods ✔✔1. Solvent spray 2. Steam cleaning 3. Emulsion cleaning 4. Alkaline cleaners Common fabrication defects ✔✔1. Laminations 2. Gouges 3. Rough welds 4. Corners Common design defects ✔✔1. Inaccessible areas 2. Welds 3. Gaps 4. Dissimilar metals 5. Overlapping surfaces Factors that may affect surface prep. ✔✔1. Residues-oils, grease, soil 2. Chemical salts residue 3. Rust on surface 4. Mill scale 5. Anchor pattern issues Surface prep should be inspected a minimum of what 3 times? ✔✔1. Before surface prep. 2. After prep, before coating 3. Between coating applications (multiple coats) Inspectors responsibilities as they relate to spec. ✔✔Observe and report all technical aspects of a coating project 5 Formal specification sections ✔✔1. Scope of work 2. Terms and Definitions 3. Reference standards and codes 4. Safety 5. Surface preparation Oil based coatings applied over alkaline surfaces may result in: ✔✔Saponification: High Ph forms a soap like material which reacts between the two coatings Industrial and marine coatings are commonly referred to by: ✔✔Generic resin type Main ingredients for hydration coating to cure ✔✔Same level of humidity as surrounding air Definition of induction time: ✔✔Period of time after mixing but before application 3 Polymerization coating cure types ✔✔1. Epoxies 2. Polyurethanes 3. Polyureas 2 Characteristics of oxidation cure coatings ✔✔1. Cure by reaction w/atmospheric oxygen 2. Main ingredient is a drying oil modified w/synthetic molecules 3 convertible coating curing mechanisms ✔✔1. Oxidation 2. Hydration 3. Fusion 2 classifications for curing mechanisms ✔✔1. Convertible 2. Non-convertible 2 Non-convertible coating types ✔✔1. Evaporation cure 2. Coalescence cure Define corrosion: ✔✔Deterioration of a substance, usually a metal, or its properties because of a reaction with the environment What is passivation? ✔✔A reduction of the anodic reaction rate of an electrode involved in corrosion What are the elements of a corrosion cell? ✔✔1. Anode 2. Cathode 3. Metallic pathway 4. Electrolyte Describe what happens at the anode. ✔✔Metal deterioration: Metal is transformed into positively charged ions. Metallica iron is first converted into another substance. Function of electrolyte? ✔✔Medium that conducts ionic current Function of metallic pathway? ✔✔Connects anode and cathode allows passage of electrons from where they are generated at the anode to the cathode What is the galvanic series? ✔✔List of materials in order of corrosion potential most to least easily corroded General rules of galvanic corrosion ✔✔1. When dissimilar metals are connected the most active (anodic) metal corrodes more rapidly. More noble (cathodic) is protected and corrodes less. 2. As potential difference increases the rate of corrosion increases 3. Corrosion rates increase as potential differences between metals increase. Factors that affect corrosion rates ✔✔1. Oxygen 2. Temperature 3. Chemical salts 4. Humidity 5. Pollutants and acid gases General Corrosion ✔✔Uniform loss of material over an entire surface and general thinning of affected surface SSPC-SP5/NACE 1 limits staining to _________per each unit area ✔✔0% Describe high voltage detectors ✔✔Sensitive electronic devices powered by batteries with output voltages from 800-60,000 V Localized corrosion ✔✔Occurs at discrete sites and often in areas that are difficult to inspect Tools/methods for corrosion control ✔✔1. Design 2. Inhibitors 3. Material selection 4. Cathodic protection 5. Protective coatings 6. Alteration of environment Define NACE inspectors role ✔✔Observe and report quality of work performed noting conformance or deviation Inspectors responsibility when it comes to safety ✔✔Knowledgeable enough to recognize and report violations that will affect the project Surface prep tests and coating tests ✔✔1. Wet film thickness 2. Dry film thickness 3. Holiday detection 4. Holiday detection 5. Psychrometer 6. Testex tape Documentation types ✔✔1. Daily reports 2. Inspection log 3. Routine reports Characteristics of a good report ✔✔Accurate statements of fact that are complete, clear and concise Inspectors responsibility pertaining to project specifications ✔✔Perform as part of an effective team to ensure spec. is followed as written or formally amended to document the results Info on product data sheet ✔✔1. Technical characteristics 2. Product performance Type of info on MSDS ✔✔1. Toxicity 2. PPE 3. Reactivity 4. Storage 5. Disposal 6. Spill handling SSPC-SP6/NACE 3 limits staining to _______per each unit area ✔✔No more than 33% Define difference in QA and QC ✔✔QC is a procedure intended to assure that a product or service meets requirements. QA is a systematic process that checks whether a product or service is meeting specified requirements Incorrect application temp. defects ✔✔1. Blistering 2. Pinholing 3. Cratering 4. Dry spray 5. Mud cracking Define relative humidity ✔✔Amount of moisture in air compared to the saturation level Define dew point temperature ✔✔Temp at which moisture begins to form. Temp to which a volume of air must be cooled to reach saturation Effects of wind on a coating project ✔✔1. Blow abrasives into coating area 2. Excessive drift/overspray of coatings 3. accelerated solvent evaporation 4. Formation of dry spray Electronic hygrometer errors ✔✔1. Reading taken in sunlight 2. Instrument left in place to long 3. Instrument removed before stabilized Process for using sling psychrometer ✔✔1. Saturate sock w/clean water 2. Whirl instrument rapidly for 40 sec. 3. Read wet bulb temperature 3 desirable coating properties ✔✔1. Chemical resistance 2. Water resistance 3. Ease of application 2 Coating classifications ✔✔1. Organic 2. Inorganic Primary components of liquid applies coating ✔✔1. Pigment 2. Binder 3. Additive 4. Solvent 3 Methods how coating provides corrosion control ✔✔1. Barrier coatings 2. Inhibitive coatings 3. Sacrificial coatings (cathodic protection) 3 Ways coating can adhere ✔✔1. Chemical 2. Mechanical 3. Polar SSPC-SP10/NACE 2 limits staining to ______per each unit area ✔✔50% Visual standards for abrasive blasting ✔✔SSPC-VIS 1 2 Abrasive blasting methods ✔✔1. Centrifugal blasting 2. Dry grit blast cleaning 4 Examples of power tool cleaning ✔✔1. Rotary wire brush 2. Grinder 3. Needle scaler 4. Impact tools Power tool cleaning standard ✔✔SSPC-SP3 3 Advantages of centrifugal blast equipment ✔✔1. Good for large, flat areas 2. Lower production costs 3. good for stationary set-ups The specifies level of surface cleanliness must be achieved and maintained ✔✔Prior to and during coating 2 Types of abrasive blast nozzles ✔✔1. Venturi 2. Straight bore What percentage of NACE standards pertain to coatings? ✔✔Approx. 50% Definition of a standard ✔✔Established norm or requirement written by an industry professional Type of high voltage detector used for concrete ✔✔Constant current DC Conductive wire ✔✔Corresponds to a metallic pathway in a corrosion cell Positive electrode ✔✔(Carbon, graphite) corresponds to the cathode in a corrosion cell Electrolyte mediums ✔✔Moist ammonium chloride and zinc chloride [Show More]

Last updated: 2 years ago

Preview 1 out of 17 pages

Buy this document to get the full access instantly

Instant Download Access after purchase

Buy NowInstant download

We Accept:

Also available in bundle (1)

Click Below to Access Bundle(s)

NACE CP1 Bundled Exams Questions and Answers (2022/2023) Already Passed

NACE CP1 Bundled Exams Questions and Answers (2022/2023) Already Passed

By Nutmegs 2 years ago

$22

16

Reviews( 0 )

$10.00

Can't find what you want? Try our AI powered Search

Document information

Connected school, study & course

About the document

Uploaded On

Apr 18, 2023

Number of pages

17

Written in

All

Additional information

This document has been written for:

Uploaded

Apr 18, 2023

Downloads

0

Views

145

.png)