Mathematics > QUESTIONS & ANSWERS > Lehigh University ISE 131 HW_ IE 131 Homework Problems. Questions & Solutions (All)

Lehigh University ISE 131 HW_ IE 131 Homework Problems. Questions & Solutions

Document Content and Description Below

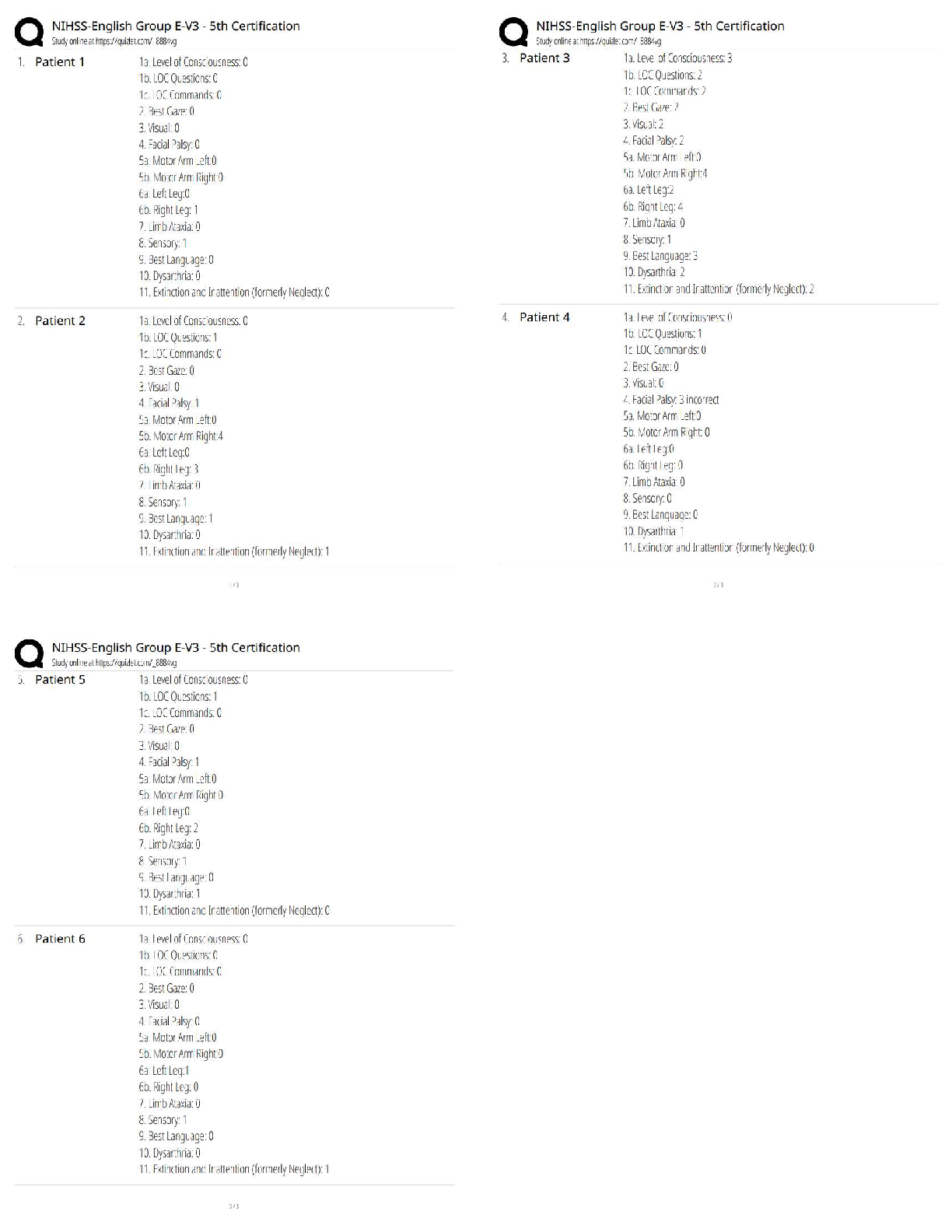

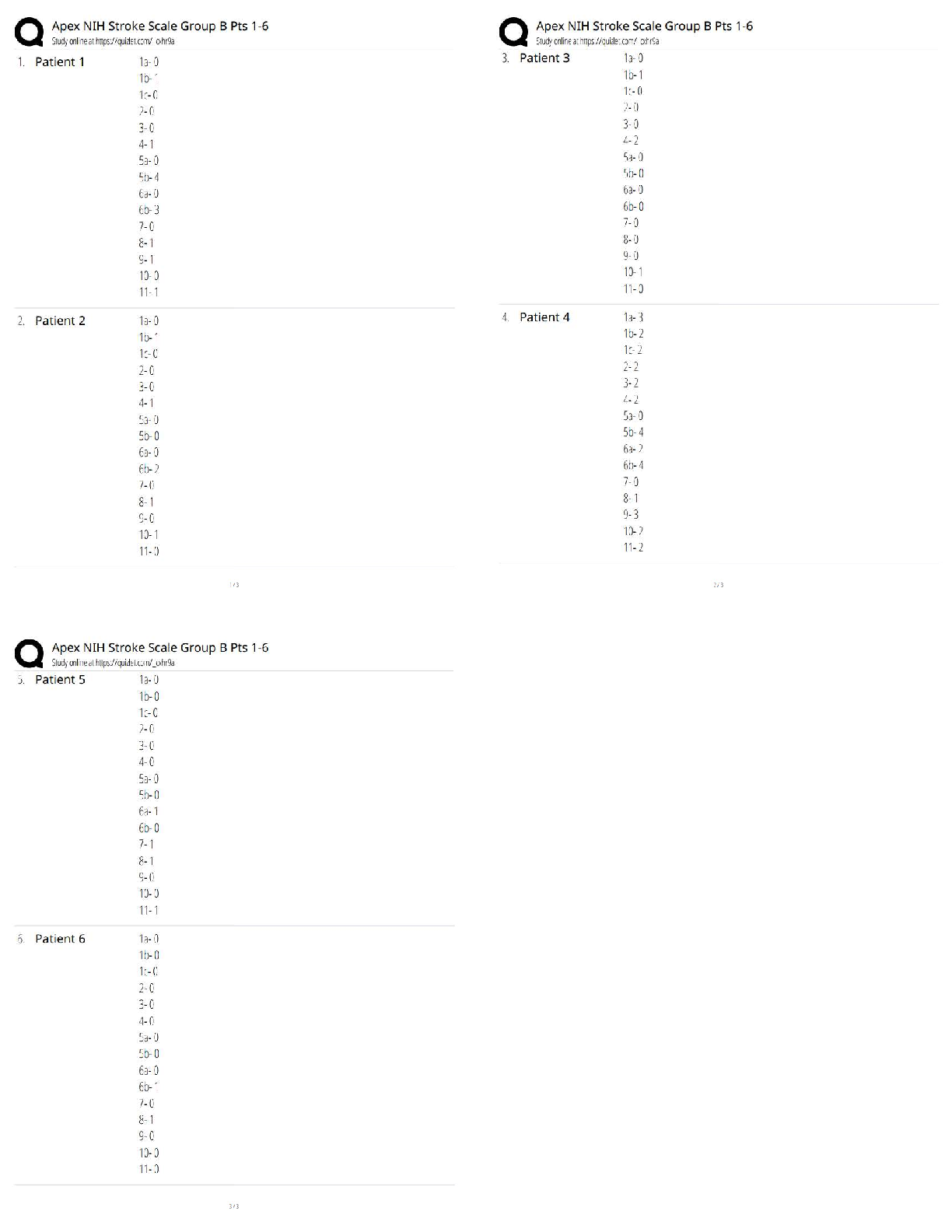

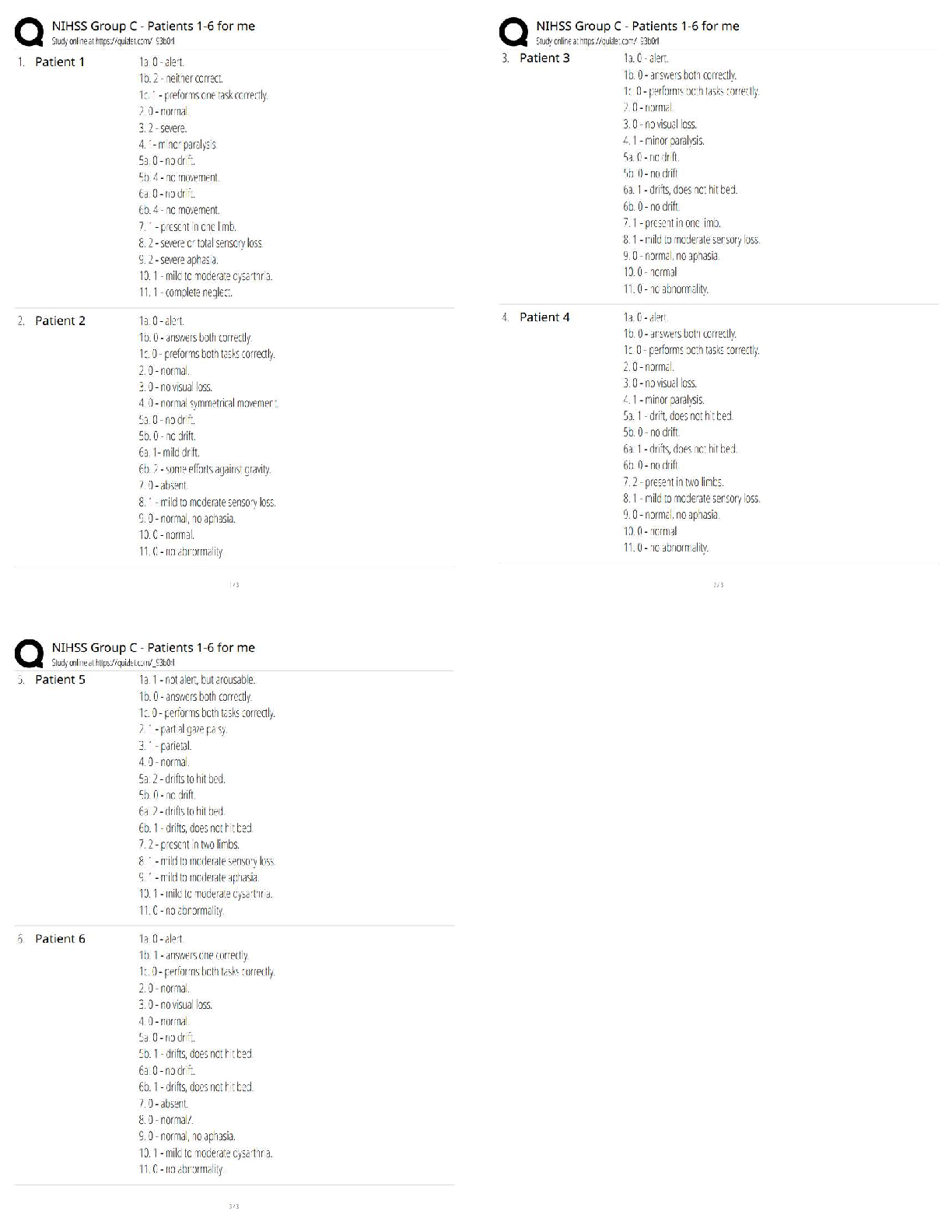

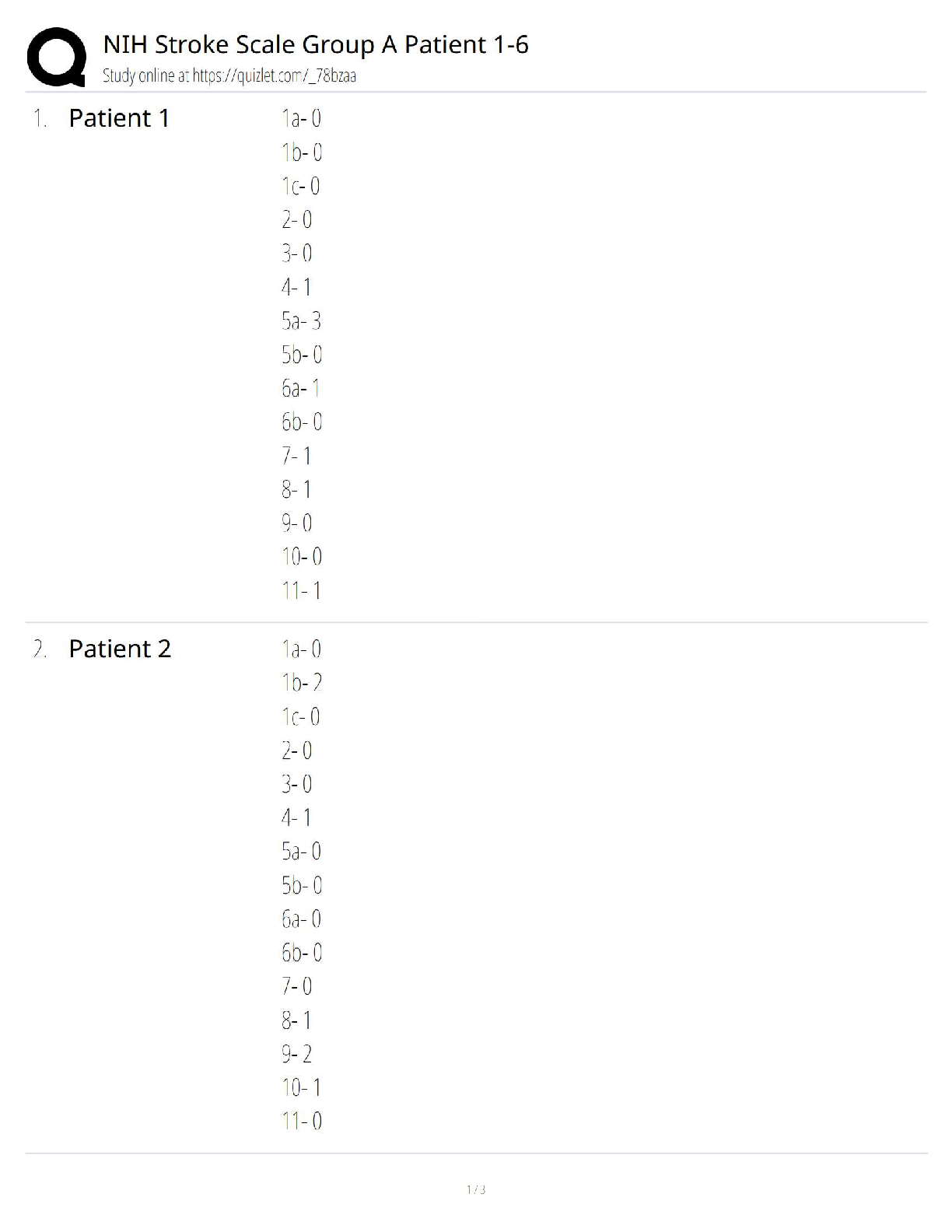

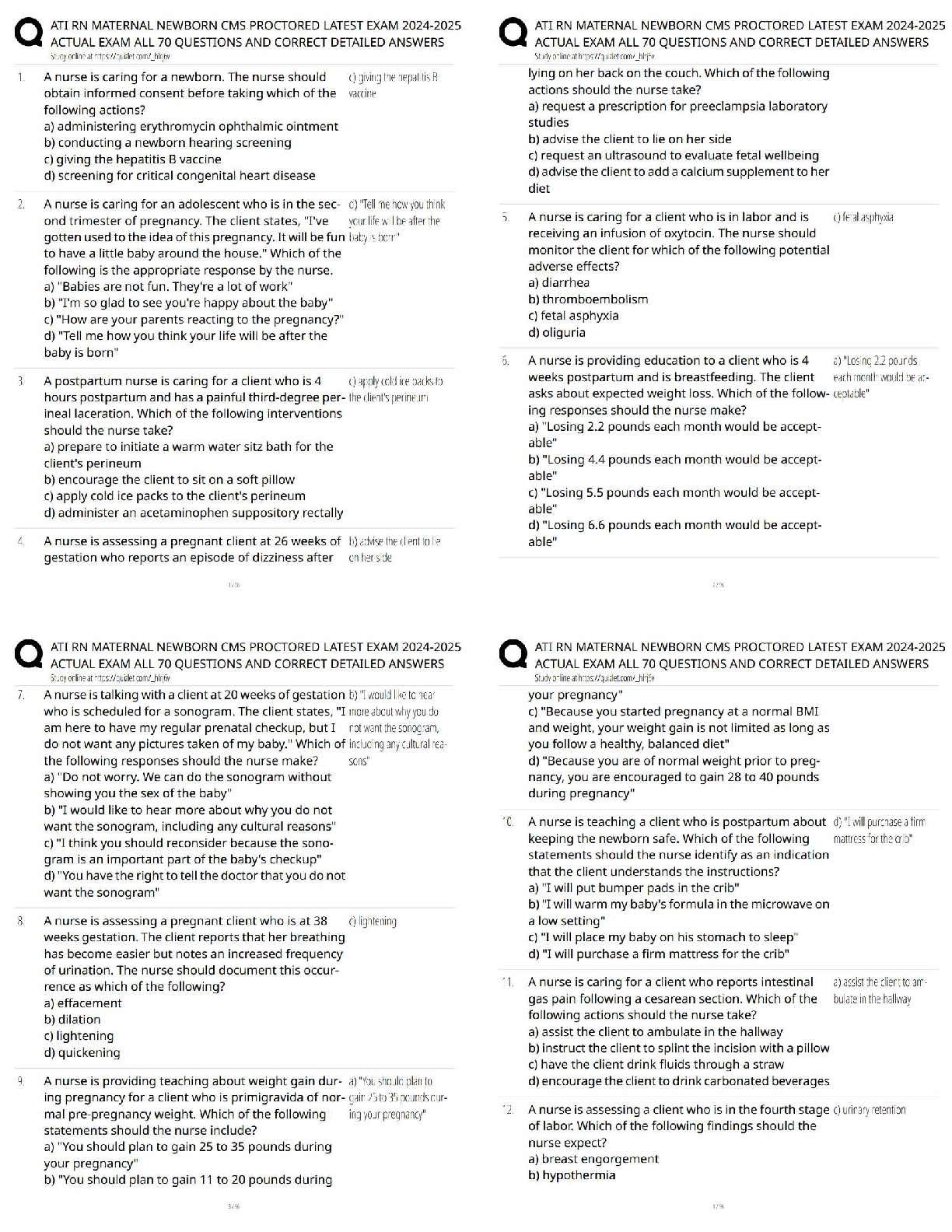

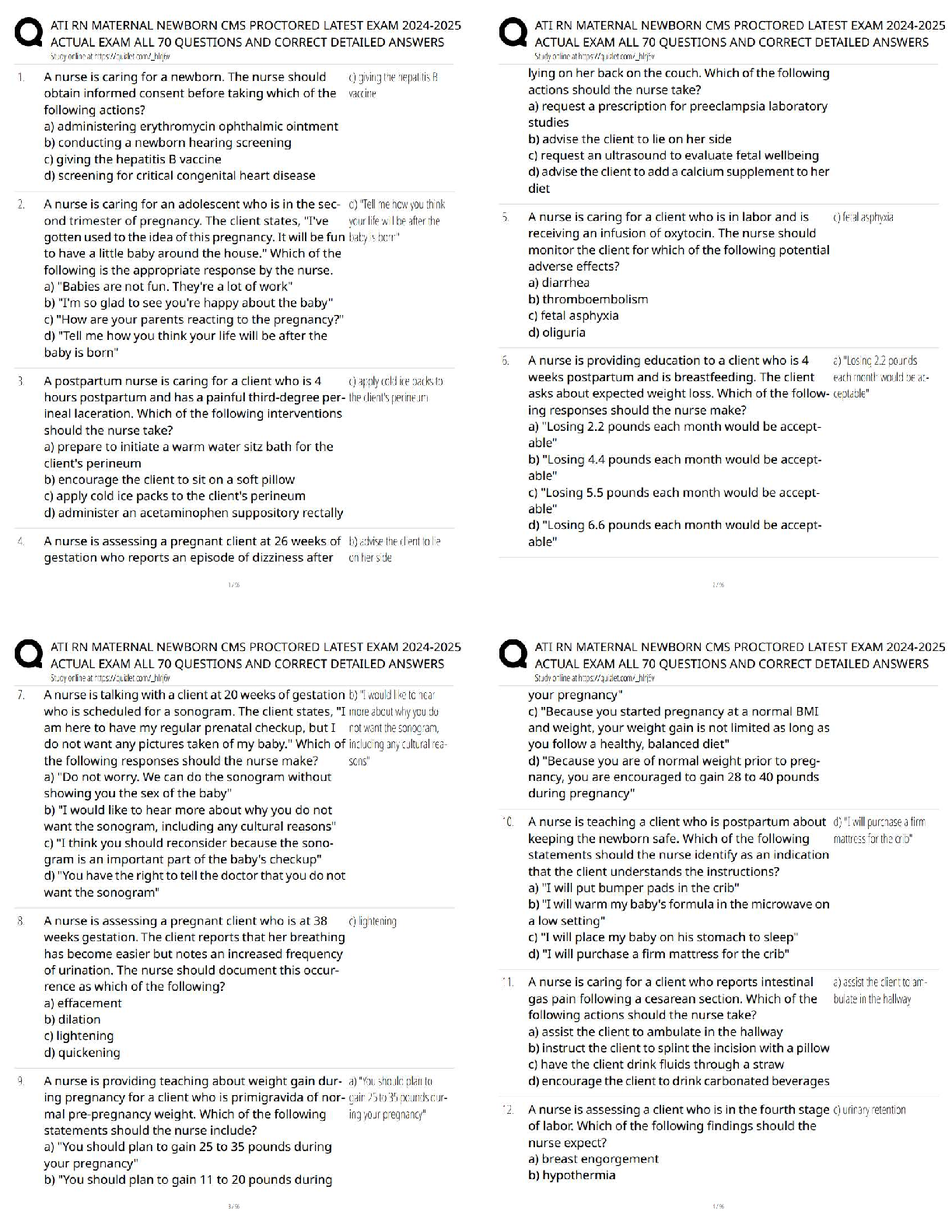

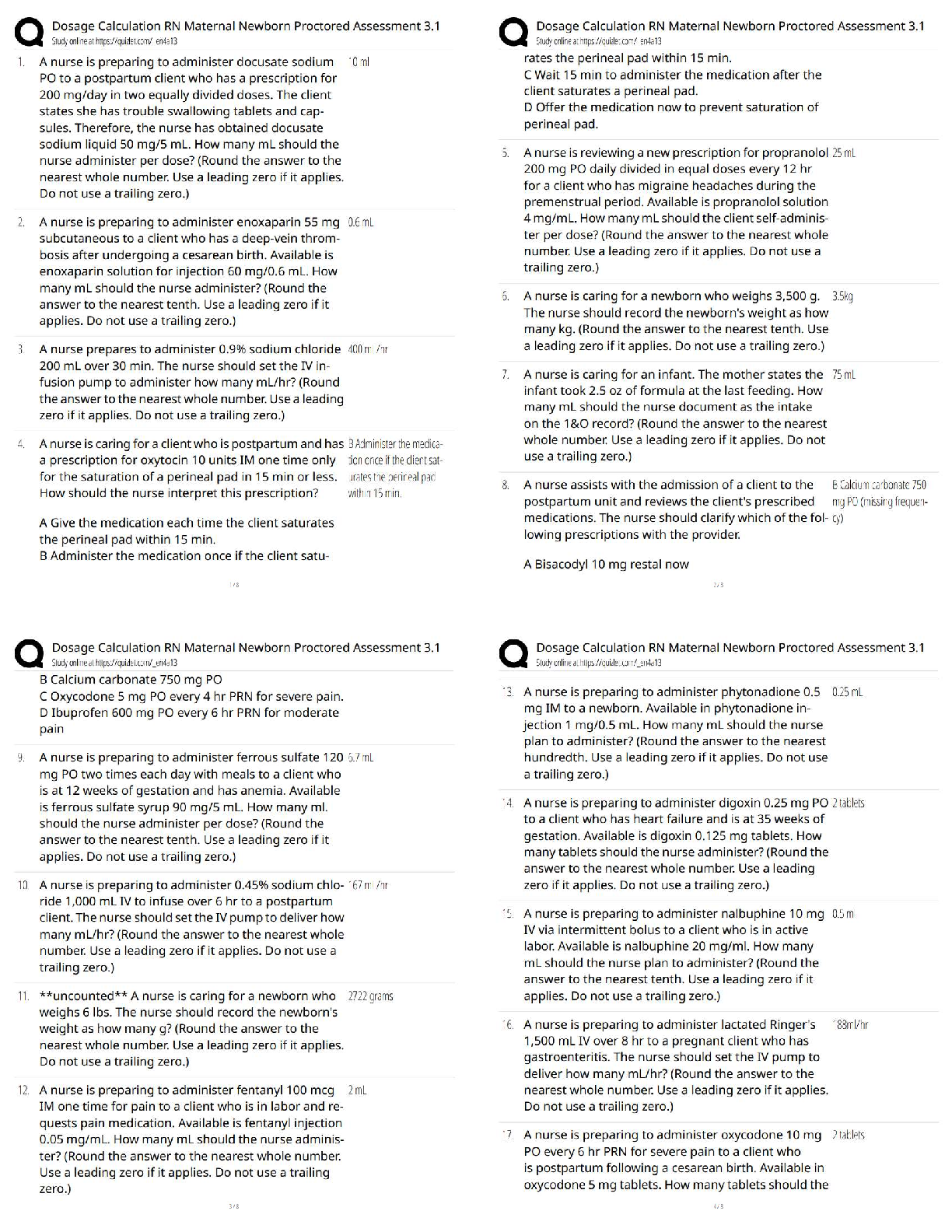

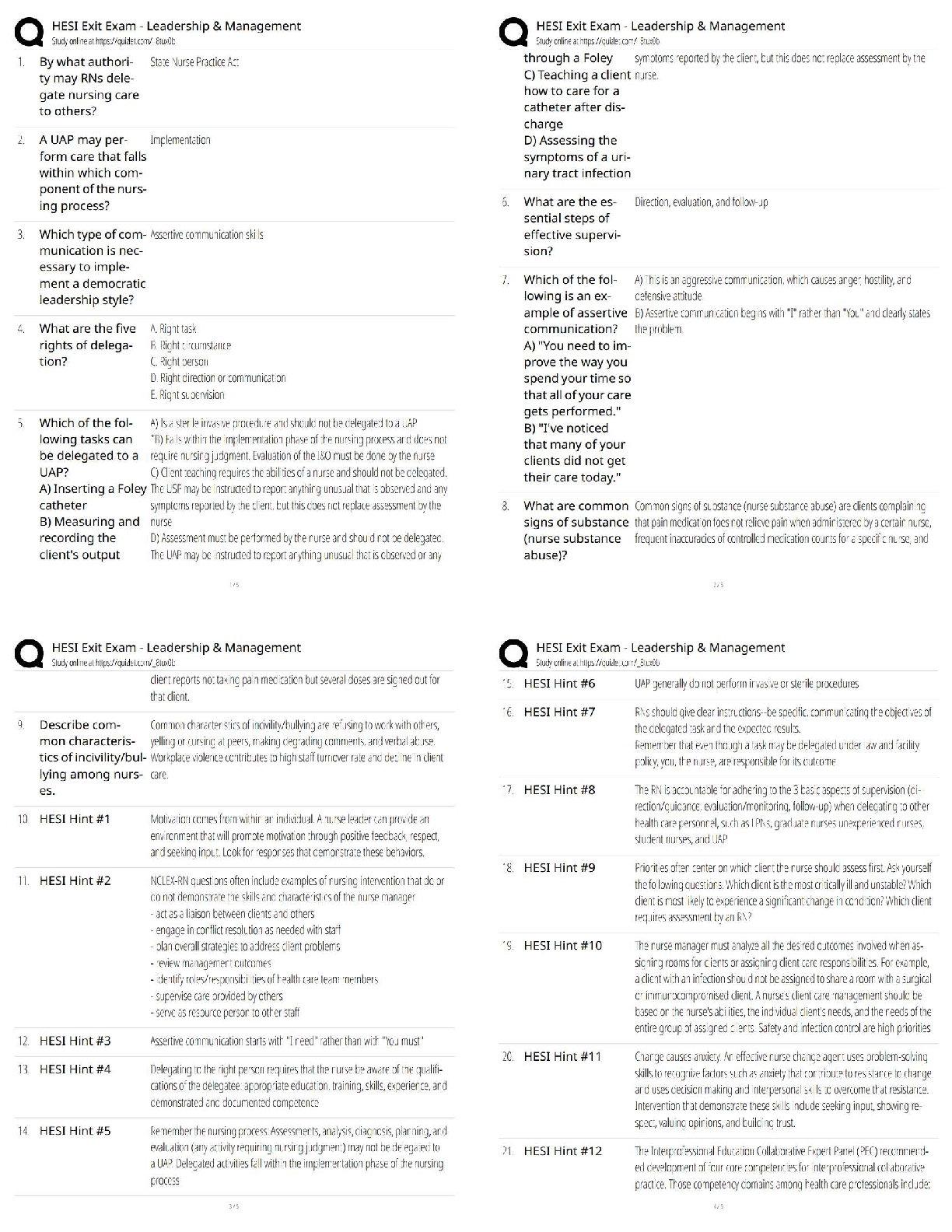

IE 131 Homework Problems due Feb 07, 2007 4.3 A manual assembly line is being planned for an assembled product whose work content time = 47.2 min. The line will be operated 2000 hr/yr. The annual de ... mand anticipated for the product is 100,000 units. Based on previous assembly lines used by the company, the proportion of uptime on the line is expected to be 94%, the line balancing efficiency will be 92%, and the repositioning time lost each cycle will be 6 sec. The line will be designed with 1 worker/station. Determine (a) the required hourly production rate of the line, (b) the cycle time, (c) the ideal minimum number of workers required, and (d) the actual number of workers required based on the efficiencies given. 4.7 The work content for a product assembled on a manual production line is 48 min. The work is transported using a continuous overhead conveyor that operates at a speed of 5 ft/min. There are 24 workstations on the line, one-third of which have two workers; the remaining stations each have one worker. Repositioning time per worker is 9 sec, and uptime efficiency of the line is 95%. (a) What is the maximum possible hourly production rate if the line is assumed to be perfectly balanced? (b) If the actual production rate is only 92% of the maximum possible rate determined in part (a), what is the balance delay on the line? (c) If the line is designed so that the tolerance time is 1.3 times the cycle time, what is the total length of the production line? (d) What is the elapsed time a product spends on the line? 4.23 A manual assembly line is being planned to produce a small consumer appliance. The work elements, element times, and precedence constraints are indicated in the table below. The workers will work for 420 min/shift and must produce 350 units/day. A mechanized conveyor, moving at a speed of 1.4 m/min will transport work units through stations. Manning level is 1.0, and repositioning time is 0.1 min. Because worker service time at each station is variable, it has been decided to use a tolerance time that is 1.5 times the cycle time. (a) Determine the ideal minimum number of workers. (b) Use the largest candidate rule to solve the line balancing problem. (c) For your line balancing solution, compute the balancing efficiency. Determine (d) spacing between work units on the line and (e) required length of each workstation to satisfy the specifications of the line. [Show More]

Last updated: 2 years ago

Preview 1 out of 4 pages

Buy this document to get the full access instantly

Instant Download Access after purchase

Buy NowInstant download

We Accept:

Reviews( 0 )

$4.00

Can't find what you want? Try our AI powered Search

Document information

Connected school, study & course

About the document

Uploaded On

Jan 13, 2023

Number of pages

4

Written in

All

Additional information

This document has been written for:

Uploaded

Jan 13, 2023

Downloads

0

Views

43