WGU C215 Operations Management -

Objective Assessment Prep Guide &

Terminologies Combo Study Guide

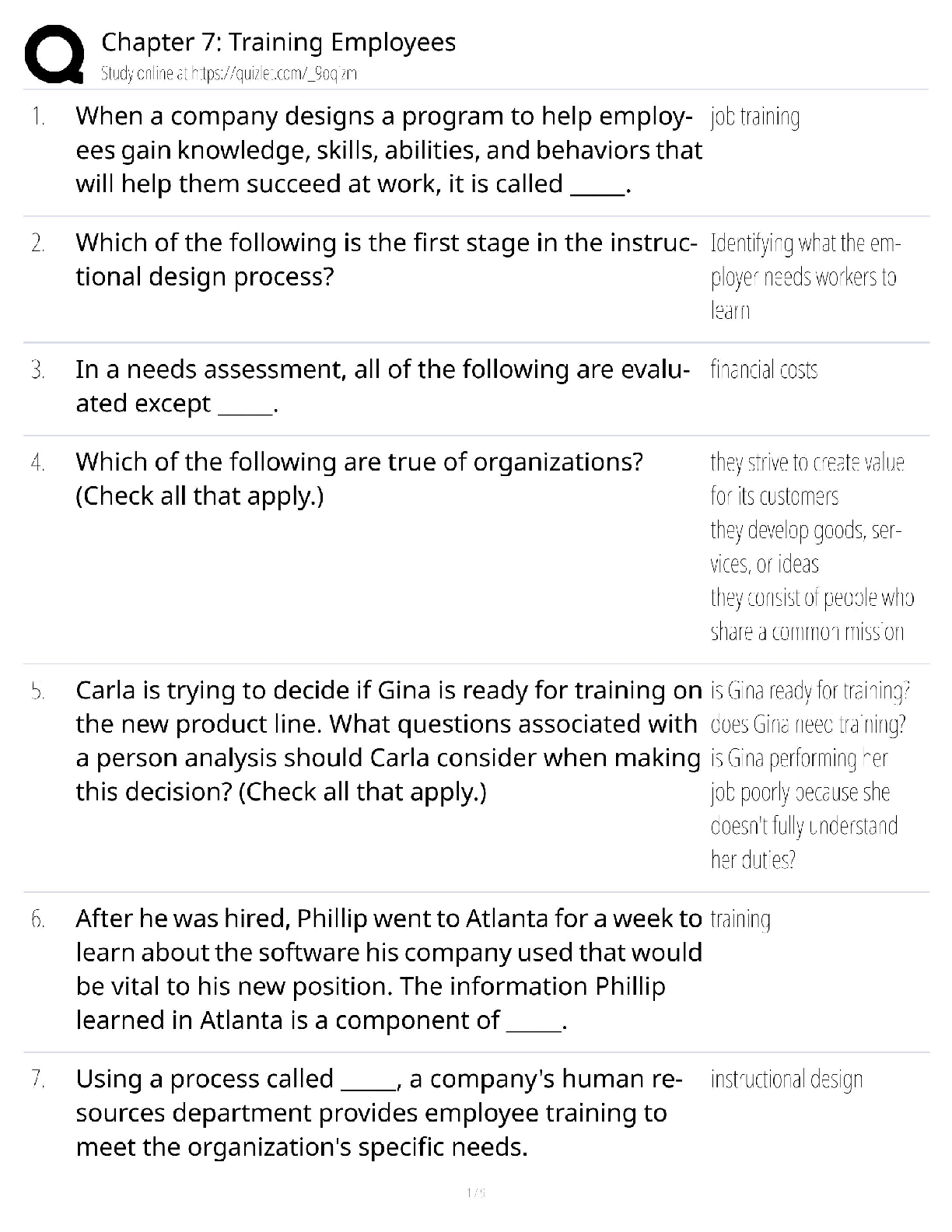

1. customer focus

2. continuous improvement

3. employee empowerment

4. use of quality tools

5. product design

6.

...

WGU C215 Operations Management -

Objective Assessment Prep Guide &

Terminologies Combo Study Guide

1. customer focus

2. continuous improvement

3. employee empowerment

4. use of quality tools

5. product design

6. process management

7. managing supplier quality ✔✔Total Quality Management (TQM) Philosophy

Basic function of Six Sigma. Measures the process potential and performance of processes. The

higher the range of Cpk, the improved is the ability of the process to complete its necessities. Uses

both the process variability and the process specifications to determine whether the process is

"capable." ✔✔Process Capability Index (Cpk)

A disciplined, data-driven approach and methodology for eliminating defects (driving toward six

standard deviations between the mean and the nearest specification limit) in any process - from

manufacturing to transactional and from product to service. ✔✔Six Sigma

The theoretical maximum output of a system in a given period under ideal conditions. ✔✔Design

Capacity

The capacity a firm expects to achieve given its current operating constraints. ✔✔Effective

Capacity

proximity to customers, transportation, source of labor, community attitude, proximity to

suppliers, and many other factors. ✔✔Location AnalysisA type of process used to produce a large volume of a standardized product. ✔✔Line Processes

A type of process used to produce a small quantity of products in groups or batches based on

customer orders or specifications. ✔✔Batch Processes

A type of process used to make a one-at-a-time product exactly to customer specifications.

✔✔Project Processes

A type of process that operates continually to produce a high volume of a fully standardized

product. ✔✔Continuous Processes

Longest task in the process. ✔✔Bottleneck

A type of automated system that combines the flexibility of intermittent operations with the

efficiency of continuous operations. ✔✔Flexible Manufacturing System (FMS)

A technique for monitoring the flow of jobs between work centers. ✔✔Output/Input Control

The net increase created during the transformation of inputs into final outputs. ✔✔Value-Added

Layouts that combine characteristics of process and product layouts. ✔✔Hybrid Layouts

Table that reflects opinions of managers with regard to the importance of having any two

departments close together. ✔✔Relationship Chart (REL)

The shortest distance between two locations using north-south and east-west movements.

✔✔Rectilinear DistanceTable that gives the number of trips or units of product moved between any pair of departments.

✔✔From-To Matrix

Schematic showing the placement of resources in a facility. ✔✔Block Plan

The average of the observation times for each of the work elements. ✔✔Mean Observed Times

The mean observed time multiplied by the performance rating factor by the frequency of

occurrence. ✔✔Normal Time

The length of time it should take a qualified worker using appropriate process and tools to complete

a specific job, allowing time for personal fatigue and unavoidable delays. ✔✔Standard Time

A philosophy designed to achieve high-volume production through elimination of waste and

continuous improvement. Based on a "pull" system rather than a "push" system. The three elements

are just-in-time manufacturing, total quality management, and respect for people. ✔✔Just-in-Time

(JIT)

A card that specifies the exact quantity of product that needs to be produced. ✔✔Kanban card

A philosophy of neverending improvement. ✔✔Continuous Improvement

Supplies materials or services directly to the processing facility. ✔✔Tier One Suppliers

Directly supplies materials or services to a tier one supplier in the supply chain. ✔✔Tier Two

Suppliers

Directly supplies materials or services to a tier two supplier in the supply chain. ✔✔Tier Three

SuppliersManagement of the flow of materials from suppliers to customers in order to reduce overall cost

and increase responsiveness to customers. ✔✔Supply Chain Management (SCM)

Determines the labor and machine resources needed to fill the open and planned orders generated

by the MRP. ✔✔Capacity Requirements Planning (CRP)

A system that uses the MRP, inventory record data, and BOM to calculate material requirements.

✔✔Material Requirements Planning (MRP)

Large software programs used for planning and coordinating all resources throughout the entire

enterprise. ✔✔Enterprise Resource Planning (ERP)

Includes the budgeted levels of finished products, inventory, backlogs, workforce size, and

aggregate production rate needed to support the marketing plan. ✔✔Aggregate Plans

Businesses to outsource elements of the company's distribution and fulfillment services. specialize

in integrated operation, warehousing and transportation services customized to customers' needs

based on the demands and delivery service requirements for their products and material ✔✔ThirdParty Logistics (3PL)

the world's leading supply chain framework, linking business processes, performance metrics,

practices and people skills into a unified structure. The goals are to increase the speed of system

implementations, support organizational learning goals, and improve inventory turns. ✔✔Supply

Chain Operations Reference model (SCOR)

Initiation, Planning, Execution and Closure. ✔✔Project Life Cycle Phases

A plan for produced in each time period such as production, staffing, inventory, etc.linked to manufacturing where the plan indicates when and how much of each product will be

demanded.

It gives production, planning, purchasing, and top management the information needed to plan and

control the manufacturing operation. ✔✔Master Production Schedule (MPS)

The meaning of quality as defined by the customer. ✔✔Total Quality Management (TQM)

network diagramming notation that places activities in the nodes and arrows to signify precedence

relationships ✔✔activity-on-node

provides users with information on services and products and provides an opportunity for suppliers

to advertise ✔✔advertising revenue model

companies receive a referral fee for directing business to an affiliate ✔✔affiliate revenue model

includes the budgeted levels of finished products, inventory, backlogs, workforce size, and

aggregate production rate needed to support the marketing plan ✔✔aggregate plan

computer software packages for designing process layouts ✔✔ALDEP and CRAFT

the amount of time the analyst allows for personal time, fatigue, and unavoidable delays

✔✔allowance factor

brings work to the worker rather than the worker to the workplace ✔✔alternative workplace

inventory built in anticipation of future demand ✔✔anticipation inventory

sets up and runs ERP systems ✔✔application service provider (ASP)costs incurred in the process of uncovering defects ✔✔appraisal costs

produces standard components that can be combined to customer specifications ✔✔assemble-toorder strategy

causes that can be identified and eliminated ✔✔assignable causes of variation

a method using telephone models to send digital orders to suppliers ✔✔automated order entry

system

unfilled customer orders ✔✔back orders

starts with the due date for an order and works backward to determine the start date for each activity

✔✔backward scheduling

scheduling method that determines when the job must be started to be done on the due date

✔✔backward scheduling

a type of process used to produce a small quantity of products in groups or batches based on

customer orders or specifications ✔✔batch process

degree to which the job is intrinsically satisfying to the employee ✔✔behavioral feasibility

studying the business practices of other companies for purposes of comparison ✔✔benchmarking

the volume of output that results in the lowest average unit cost ✔✔best operating level

typically represents project activities ✔✔beta probability distributionlists all the subassemblies, component parts, and raw materials that go into an end item and shows

the usage quantity of each required ✔✔bill of material (BOM)

schematic showing the placement of resources in a facility ✔✔block plan

longest task in the process ✔✔bottleneck

technique used to compute the amount of goods that must be sold just to cover costs ✔✔breakeven analysis

a philosophy that encompasses the entire organization ✔✔broad view of JIT

tasks and procedures are important only if they meet the company's overall goals ✔✔broad view

of the organization

inaccurate or distorted demand information created in the supply chain ✔✔bullwhip effect

a long-range plan for a business ✔✔business strategy

electronic commerce between businesses ✔✔business-to-business (B2B)

businesses selling to and buying from other businesses ✔✔business-to-business e-commerce

on-line businesses sell to individual consumers ✔✔business-to-consumer e-commerce (B2C)

electronic commerce between businesses and their customers ✔✔business-to-customers (B2C)

the maximum output rate that can be achieved by a facility ✔✔capacityadditional capacity added to regular capacity requirements to provide greater flexibility

✔✔capacity cushion

the process of establishing the output rate that can be achieved by a facility ✔✔capacity planning

a rough-cut capacity planning technique. MPS items are multiplied by historically determined

planning factors for key resources ✔✔capacity planning using overall planning factors (CPOPF)

determines the labor and machine resources needed to fill the open and planned orders generated

by the MRP ✔✔capacity requirements planning (CRP)

percentage measure of how well available capacity is being used ✔✔capacity utilization

a group of options that allow the firm to change its current operating capacity ✔✔capacity-based

options

a chart that identifies potential causes of particular quality problems ✔✔cause-and-effect diagram

placement of dissimilar machines and equipment together to produce a family of products with

similar processing requirements ✔✔cell manufacturing

a planning approach that varies production to meet demand each period ✔✔chase aggregate plan

a list of common defects and the number of observed occurrences of these defects ✔✔checklist

random causes that cannot be identified ✔✔common causes of variation

capabilities that the operations function can develop in order to give a company a competitive

advantage in its market ✔✔competitive prioritiesparts or subassemblies used in the final product ✔✔components

how well a product or service meets the targets and tolerances determined by its designers

✔✔conformance to specifications

a mathematical model in which one is trying to maximize or minimize some quantity, while

satisfying a set of constraints ✔✔constrained optimization problem

limitations or requirements that must be satisfied ✔✔constraints

a philosophy of never-ending improvement ✔✔continuous improvement

a philosophy of never-ending improvement ✔✔continuous improvement (kaizen)

a type of process that operates continually to produce a high volume of a fully standardized product

✔✔continuous process

charts used to evaluate whether a process is operating within set expectations ✔✔control charts

the unique strengths of a business ✔✔core competencies

a competitive priority focusing on low cost ✔✔cost

the longest sequential path through the network diagram ✔✔critical path

network planning technique, with deterministic times, used to determine a project's planned

completion date and identify the project's critical path ✔✔critical path method (CPM)the coordinated interaction and decision making that occur among the different functions of the

organization ✔✔cross-functional decision making

software solutions that enable the firm to collect customer-specific data ✔✔customer relationship

management (CRM)

the ability to satisfy customer requirements ✔✔customer service

the meaning of quality as defined by the customer ✔✔customer-defined quality

electronic commerce between customers ✔✔customer-to-customer (C2C)

prespecified items are counted daily ✔✔cycle counting

modeling tool used to evaluate independent decisions that must be made in sequence ✔✔decision

tree

quantities under the control of the decision maker ✔✔decision variables

broad view of operations, simplicity, continuous improvement, visibility, and flexibility

✔✔defining beliefs of JIT

a group of options that respond to demand fluctuations through the use of inventory or back orders,

or by shifting the demand pattern ✔✔demand-based options

a Japanese award given to companies to recognize efforts in quality improvement ✔✔Deming

Prize

proven capacity calculated from actual performance data ✔✔demonstrated capacitydemand for component parts is based on the number of end items being produced ✔✔dependent

demand

the maximum output rate that can be achieved by a facility under ideal conditions ✔✔design

capacity

assumption that the activity duration is known with certainty ✔✔deterministic time estimate

a condition in which the cost of each additional unit made increases ✔✔diseconomies of scale

finished goods in the distribution system ✔✔distribution inventory

responsible for movement of material from the manufacturer to the customer ✔✔distribution

management

time when the job is supposed to be finished ✔✔due date

the expected length of time the different capacity level is needed ✔✔duration of the change

using the Internet and Web to transact business ✔✔e-commerce

the cost of the job should be less than the value it adds ✔✔economic feasibility

a condition in which the average cost of a unit produced is reduced as the amount of output is

increased ✔✔economies of scale

the maximum output rate that can be sustained under normal conditions ✔✔effective capacityperforming activities at the lowest possible cost ✔✔efficiency

ratio of actual output to standard output ✔✔efficiency

a form of computer-to-computer communications that enables sharing business documents

✔✔electronic data interchange (EDI)

an electronic request for a quote on goods and services ✔✔electronic request for quote (eRFQs)

on-line catalogs of products made available to the general public by a single supplier ✔✔electronic

storefronts

establish standards based on previously completed time studies, stored in an organization's

database ✔✔elemental time data

identifies new products or modifications to existing products that are needed to support the

marketing plan ✔✔engineering plan

large, sophisticated software systems used for identifying and planning the enterprise-wide

resources needed to coordinate all activities involved in producing and delivering products

✔✔enterprise resource planning (ERP)

monitoring the external environment for changes and trends to determine business opportunities

and threats ✔✔environmental scanning

a constraint such as 6x ₁ + 3x ₂ = 30, used to specify that a requirement must be met exactly

✔✔equality constrainta weighted average of chance events, where each chance event is given a probability of occurrence

✔✔expected value (EV)

costs associated with quality problems that occur at the customer site ✔✔external failure costs

can be performed while the machine is still running ✔✔external setup

intranets that are linked to the Internet so that suppliers and customers can be included in the

system ✔✔extranets

a procedure that can be used to evaluate multiple alternative locations based on a number of

selected factors ✔✔factor rating

a specific combination of values of the decision variables such that all of the constraints are

satisfied ✔✔feasible solution

identifies the sources and uses of funds; projects cash flows, profits, return on investment; and

provides budgets in support of the strategic business plan ✔✔financial plan

products sold to customers ✔✔finished goods

products available for shipment to the customer ✔✔finished goods inventory

scheduling that loads work centers up to a predetermined amount of capacity ✔✔finite loading

a definition of quality that evaluates how well the product performs for its intended use ✔✔fitness

for usea layout in which the product cannot be moved due to its size and all the resources have to come

to the production site ✔✔fixed-position layout

an organizational strategy in which the company attempts to offer a greater variety of product

choices to its customers ✔✔flexibility

a competitive priority focusing on offering a wide variety of goods or services ✔✔flexibility

a company can quickly adapt to the changing needs of its customers ✔✔flexibility

a schematic of the sequence of steps involved in an operation or process ✔✔flowchart

provides a cushion against unexpected demand ✔✔fluctuation inventory

facilities that are small, specialized, and focused on a narrow set of objectives ✔✔focused factories

a formal, algebraic statement of a constrained optimization problem ✔✔formulation

schedule that determines the earliest possible completion date for a job ✔✔forward scheduling

how often the work element must be done each cycle ✔✔frequency of occurrence

table that gives the number of trips or units of product moved between any pair of departments

✔✔from-to matrix

a trend in business focusing on customers, suppliers, and competitors from a global perspective

✔✔global marketplace

the process of locating facilities around the world ✔✔globalizationa constraint such as 4x ₁ + 7x ₂ ≥ 50, often used to model a requirement that must be satisfied

✔✔greater-than-or-equal-to constraint

focuses on the role of the supply chain with regard to its impact on the environment ✔✔green

supply chain management

the total-period demand for an item ✔✔gross requirements

hybrid layouts that create groups of products based on similar processing requirements ✔✔group

technology (GT) or cell layouts

the studies responsible for creating the human relations movement, which focused on giving more

consideration to workers' needs ✔✔Hawthorne studies

long-term option for increasing or decreasing capacity ✔✔hiring and firing

a chart that shows the frequency distribution of observed values of a variable ✔✔histogram

a philosophy based on the recognition that factors other than money can contribute to worker

productivity ✔✔human relations movement

a planning approach that uses a combination of level and chase approaches while developing the

aggregate plan ✔✔hybrid aggregate plan

layouts that combine characteristics of process and product layouts ✔✔hybrid layouts

the demand for an item is unrelated to the demand for other items ✔✔independent demandan industry movement that changed production by substituting machine power for labor power

✔✔Industrial Revolution

a specific combination of values of the decision variables such that at least one of the constraints

is violated ✔✔infeasible solution

scheduling that calculates the capacity needed at work centers in the time period needed without

regard to the capacity available to do the work ✔✔infinite loading

operations decisions related to the planning and control systems of the operation, such as

organization of operations, skills and pay of workers, and quality measures ✔✔infrastructure

a technique for monitoring the flow of jobs between work centers ✔✔input/output control

processes used to produce a variety of products with different processing requirements in lower

volumes ✔✔intermittent operations

costs associated with discovering poor product quality before the product reaches the customer

✔✔internal failure costs

a regular bottleneck ✔✔internal resource constraint

requires the machine to be stopped in order to be performed ✔✔internal setup

networks that are internal to an organization ✔✔intranets

a measure of inventory policy effectiveness ✔✔inventory turnovera set of international standards and a certification focusing on a company's environmental

responsibility ✔✔ISO 14000

a set of international quality standards and a certification demonstrating that companies have met

all the standards specified ✔✔ISO 9000

specifies the contents of the job ✔✔job design

a horizontal expansion of the job through increasing the scope of the work assigned ✔✔job

enlargement

a vertical expansion of the job through increased worker responsibility ✔✔job enrichment

workers shift to different jobs to increase understanding of the total process ✔✔job rotation

a philosophy designed to achieve high-volume production through elimination of waste and

continuous improvement ✔✔just-in-time (JIT)

getting the right quantity of goods at the right place at the right time ✔✔just-in-time (JIT)

philosophy

the element of JIT that focuses on the production system to achieve value-added manufacturing

✔✔just-in-time manufacturing

a Japanese term that describes the notion of a company continually striving to be better through

learning and problem solving ✔✔kaizen

a card that specifies the exact quantity of product that needs to be produced ✔✔kanban carda concept that takes a total system approach to creating efficient operations ✔✔lean systems

a constraint such as 3x ₁ + 5x ₂ ≤ 22, often used to model a limitation on the amount of a resource

that can be used ✔✔less-than-or-equal-to constraint

a planning approach that produces the same quantity each time period. Inventory and back orders

are used to absorb demand fluctuations ✔✔level aggregate plan

the value of the constraint expression to the left of the ≤, ≥, or = sign ✔✔LHS value

a type of process used to produce a large volume of a standardized product ✔✔line process

a constrained optimization problem in which all the functions involving decision variables are

linear ✔✔linear program (LP)

a procedure for evaluating location alternatives based on distance ✔✔load-distance model

model used to compare the relative effectiveness of different layouts ✔✔load-distance model

techniques for determining location decisions ✔✔location analysis

activities involved in obtaining, producing, and distributing materials and products in the proper

place and in proper quantities ✔✔logistics

a result of the quantity ordered or produced ✔✔lot-size inventory

the relative size of the change needed ✔✔magnitude of the changeitems used in support of manufacturing and maintenance ✔✔maintenance, repair, and operating

inventory (MRO)

produces products to customer specifications after an order has been received ✔✔make-to-order

strategy

produces standard products and services for immediate sale or delivery ✔✔make-to-stock strategy

an award given annually to companies that demonstrate quality excellence and establish best

practice standards in industry ✔✔Malcolm Baldrige National Quality Award

a field of study that focuses on the development of quantitative techniques to solve operations

problems ✔✔management science

the ease with which a product can be made ✔✔manufacturability

organizations that primarily produce a tangible product and typically have low customer contact

✔✔manufacturing organizations

the condition that results when market demand is less than production capacity ✔✔market

constraint

identifies the markets to be served, desired levels of customer service, product competitive

advantage, profit margins, and the market share needed to achieve the objectives of the strategic

business plan ✔✔marketing plan

the ability of a firm to highly customize its goods and services at high volumes ✔✔mass

customizationthe anticipated production schedule for the company expressed in specific configurations,

quantities, and dates ✔✔master production schedule

the anticipated build schedule ✔✔master production schedule (MPS)

the person responsible for managing, developing, reviewing, and maintaining the master schedule

✔✔master scheduler

a system that uses the MRP, inventory record data, and BOM to calculate material requirements

✔✔material requirements planning (MRP)

the average of the observation times for each of the work elements ✔✔mean observed time

process concerned with the detailed process for doing a particular job ✔✔methods analysis

a statement defining what business an organization is in, who its customers are, and how its core

beliefs shape its business ✔✔mission

the normal time that the activity is expected to take ✔✔most likely time estimate

productivity computed as a ratio of output to several, but not all, inputs ✔✔multifactor productivity

capable of performing more than one job ✔✔multifunction workers

suppliers and buyers conduct trade in a single Internet- based environment ✔✔net marketplaces

constraints of the form x ₁ ≥ 0, which are nearly universal in linear programming problems. They

are used to represent the fact that negative quantities of products cannot be made, shipped, etc.

✔✔nonnegativity constraintsthe mean observed time multiplied by the performance rating factor by the frequency of occurrence

✔✔normal time

the quantity to be maximized or minimized ✔✔objective

released manufacturing orders ✔✔open shop orders

the business function responsible for planning, coordinating, and controlling the resources needed

to produce a company's goods and services ✔✔operations management (OM)

a long-range plan for the operations function that specifies the design and use of resources to

support the business strategy ✔✔operations strategy

the feasible solution with the largest (for a maximization problem) or smallest (for a minimization)

objective value ✔✔optimal solution

the shortest time period in which the activity can be completed ✔✔optimistic time estimate

competitive priorities that must be met for a company to qualify as a competitor in the marketplace

✔✔order qualifiers

competitive priorities that win orders in the marketplace ✔✔order winners

pay based on the number of units completed ✔✔output-based (incentive) systems

work beyond normal established operation hours that usually requires a premium be paid to the

workers ✔✔overtimea technique used to identify quality problems based on their degree of importance ✔✔Pareto

analysis

productivity computed as a ratio of output to only one input (e.g., labor, materials, machines)

✔✔partial productivity

a customer service measure appropriate when customer orders vary in value ✔✔percentage of

dollar volume shipped on schedule

a customer service measure appropriate when customer orders vary in number of line items ordered

✔✔percentage of line items shipped on schedule

a customer service measure appropriate for use when orders have similar value ✔✔percentage of

orders shipped on schedule

a subjective estimate of a worker's pace relative to a normal work pace ✔✔performance rating

factor

a physical inventory is taken periodically, usually annually ✔✔periodic counting

the longest time period in which the activity will be completed ✔✔pessimistic time estimate

a diagram that describes the activities that need to be performed to incorporate continuous

improvement into the operation ✔✔plan-do-study-act (PDSA) cycle

the percentage of normal capacity the company is currently using ✔✔point of departure

the condition that results when a specific policy dictates the rate of production ✔✔policy

[Show More]

.png)