Getting to know your unit

Engineering processes, whether concerned with the manufacture of a

product or the delivery of an engineering service, are the cornerstones

of all modern industrial engineering. A single indiv

...

Getting to know your unit

Engineering processes, whether concerned with the manufacture of a

product or the delivery of an engineering service, are the cornerstones

of all modern industrial engineering. A single individual cannot carry

out any complex industrial function effectively – often the coordinated

efforts of hundreds or even thousands of people are required to

manufacture a complex product such as a car or an aeroplane. This unit

covers a range of practical and teamworking skills that are necessary

when manufacturing a product or delivering a service safely as a team.

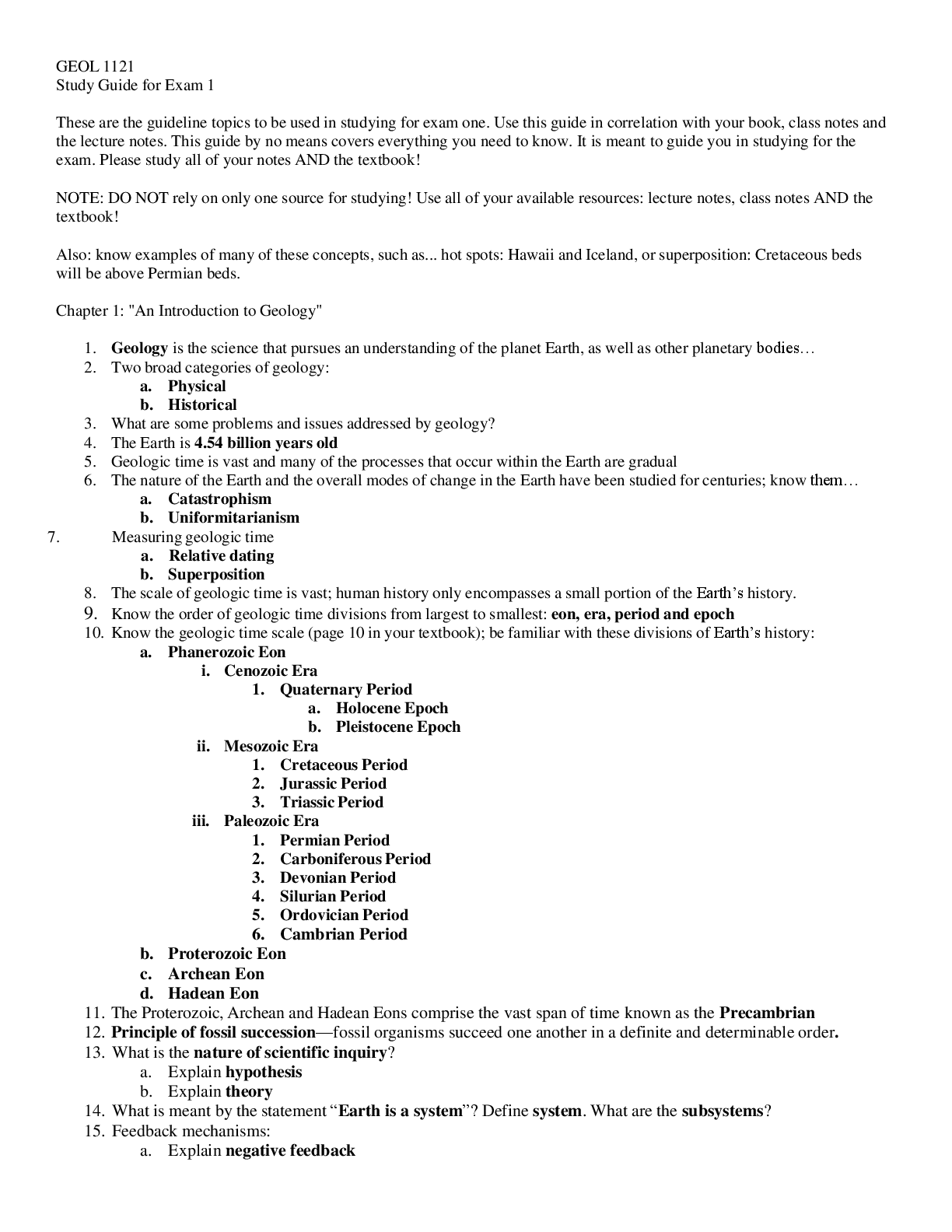

How you will be assessed

This unit will be assessed by a series of internally assessed tasks set by your tutor.

Throughout this unit you will find assessment practice activities to help you work

towards your assessment. Completing these activities will not mean that you

have achieved a particular grade, but you will have carried out useful research or

preparation that will be relevant when it comes to your final assignment.

In order for you to achieve the tasks in your assignment, it is important to check that

you have met all of the assessment criteria. You can do this as you work your way

through each assignment.

If you are hoping to gain a Merit or Distinction grade, you should also make sure that

you present the information in your assignments in the style that is required by the

relevant assessment criterion. For example, Merit criteria require you to analyse, and

Distinction criteria require you to evaluate.

The assignments set by your tutor will consist of a number of tasks designed to meet

the criteria in the table. They are likely to take the form of written reports, but may

also include activities such as the following:

▸ Reviewing and analysing case studies based on the manufacture of an engineered

product or delivery of a service in terms of the processes used and the influence of

human factors.

▸ Creating engineering drawings using computer-aided design (CAD) software.

▸ Carrying out practical engineering processes both as a team leader and as a

member of a team.

Assessment

This unit will be assessed

by a series of assignments

set by your tutor.

Getting to know your unit

75

UNIT 2Delivery of Engineering Processes Safely as a Team

Assessment criteria

This table shows what you must do in order to achieve a Pass, Merit or Distinction grade, and where you

can find activities to help you.

Pass Merit Distinction

Learning aim A Examine common engineering processes to create products or deliver

services safely and effectively as a team

A.D1

Evaluate, using high quality written

language, the effectiveness of using

different engineering processes to

manufacture a product or to deliver

a service and how human factors, as

an individual and as a team, affect

the performance of engineering

processes.

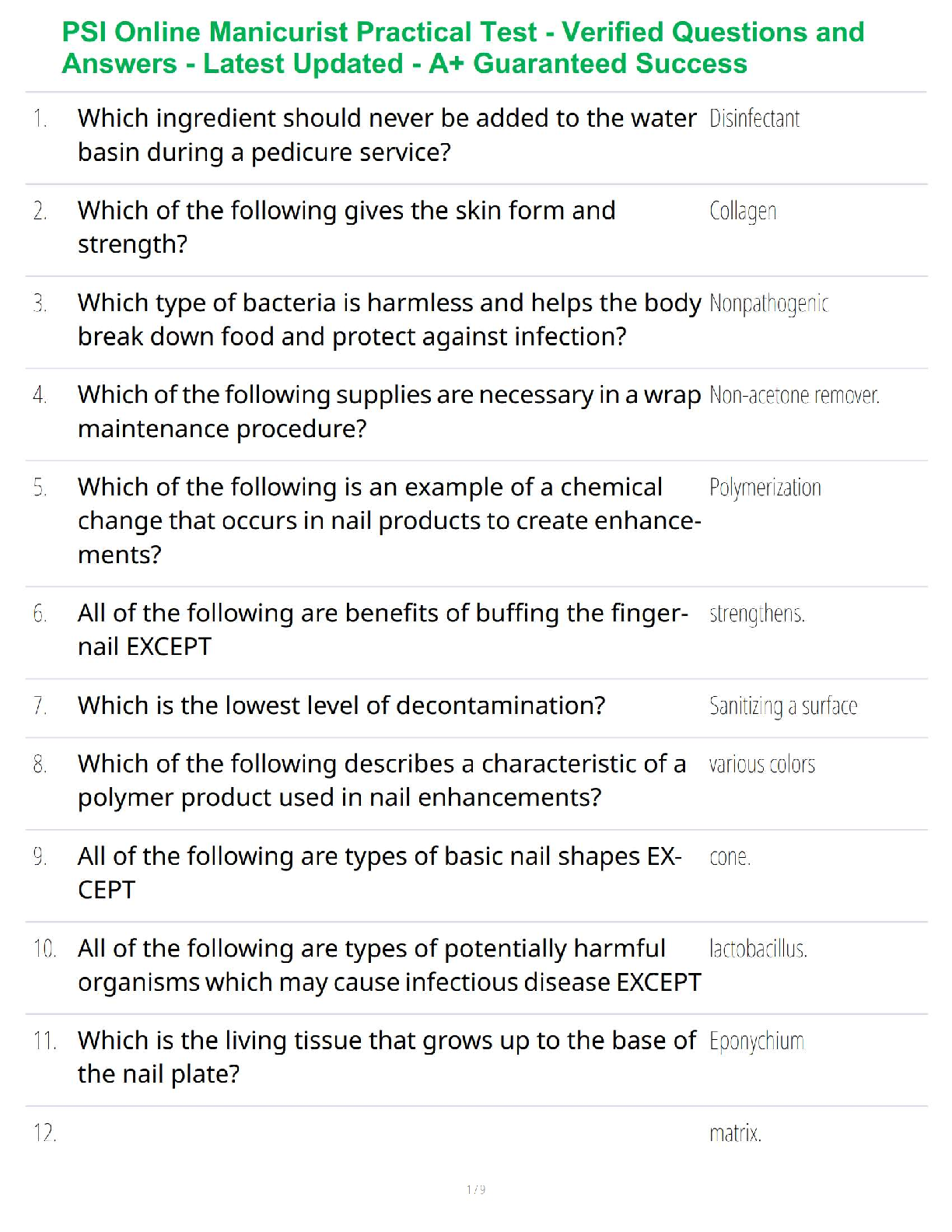

Assessment practice 2.1

A.P1

Explain how three engineering processes are used safely

when manufacturing a given product or when delivering

a given service.

Assessment practice 2.1

A.M1

Analyse why three engineering

processes are used to manufacture

a product or to deliver a service

and how human factors, as an

individual and as a team, affect

the performance of engineering

processes.

Assessment practice 2.1

A.P2

Explain how human factors, as an individual or as a team,

affect the performance of engineering processes.

Assessment practice 2.1

Learning aim B Develop two-dimensional computer-aided drawings that can be used in

engineering processes

B.D2

Refine, using layers, an accurate

orthographic projection of a

component containing at least three

different types of common feature

and a circuit diagram containing at

least six different component types

to an international standard.

Assessment practice 2.2

B.P3

Create an orthographic projection of a given component

containing at least three different types of feature.

Assessment practice 2.2

B.M2

Produce, using layers, an accurate

orthographic projection of a

component containing at least

three different types of feature

and a circuit diagram containing at

least six different component types

that mainly meet an international

standard.

Assessment practice 2.2

B.P4

Create a diagram of a given electrical circuit containing

at least six different component types.

Assessment practice 2.2

Learning aim C Carry out engineering processes safely to manufacture a product or to

deliver a service effectively as a team

C.P5

Manage own contributions to set up and organise a

team in order to manufacture a product or deliver a

service.

Assessment practice 2.3

C.M3

Manage own contributions safely

and effectively using feedback from

peers, as a team member and a team

leader, to manufacture a product or

to deliver a service.

Assessment practice 2.3

C.D3

Consistently manage own

contributions effectively using

feedback from peers, as a team

member and a team leader, to set

up, organise and manufacture a

product or deliver a service safely,

demonstrating forward thinking,

adaptability or initiative.

Assessment practice 2.3

C.P6

Produce, as an individual team member, a risk

assessment of at least one engineering process.

Assessment practice 2.3

C.P7

Set up, as an individual team member, at least one

process safely by interpreting technical documentation.

Assessment practice 2.3

C.P8

Manage own contributions safely, as a team member and

a team leader, to manufacture a batch of an engineered

product or to deliver a batch of an engineering service.

Assessment practice 2.3

76 Delivery of Engineering Processes Safely as a Team

These ideas must be developed, evaluated and refined to

achieve a viable solution. Once a solution is established, it

must be communicated effectively to the people who will

be asked to manufacture the product or deliver the service.

Preparation will include these documents:

▸ Technical specifications – define exactly what a

product or service will do.

▸ Engineering drawings – define exactly what the

individual components of a product will look like and

how they should be assembled during manufacture to

make the final product.

▸ Scale of production – defines the number of products

that need to be manufactured or the number of times

a service needs to be performed, hence dictating the

approach to manufacture or service delivery;

(see Table 2.1).

▸ Work plans – define a standard methodology that

should be followed when manufacturing a product or

delivering a service.

▸ Quality control documents – define the checks that

should take place both during and after manufacturing

a product or delivering a service.

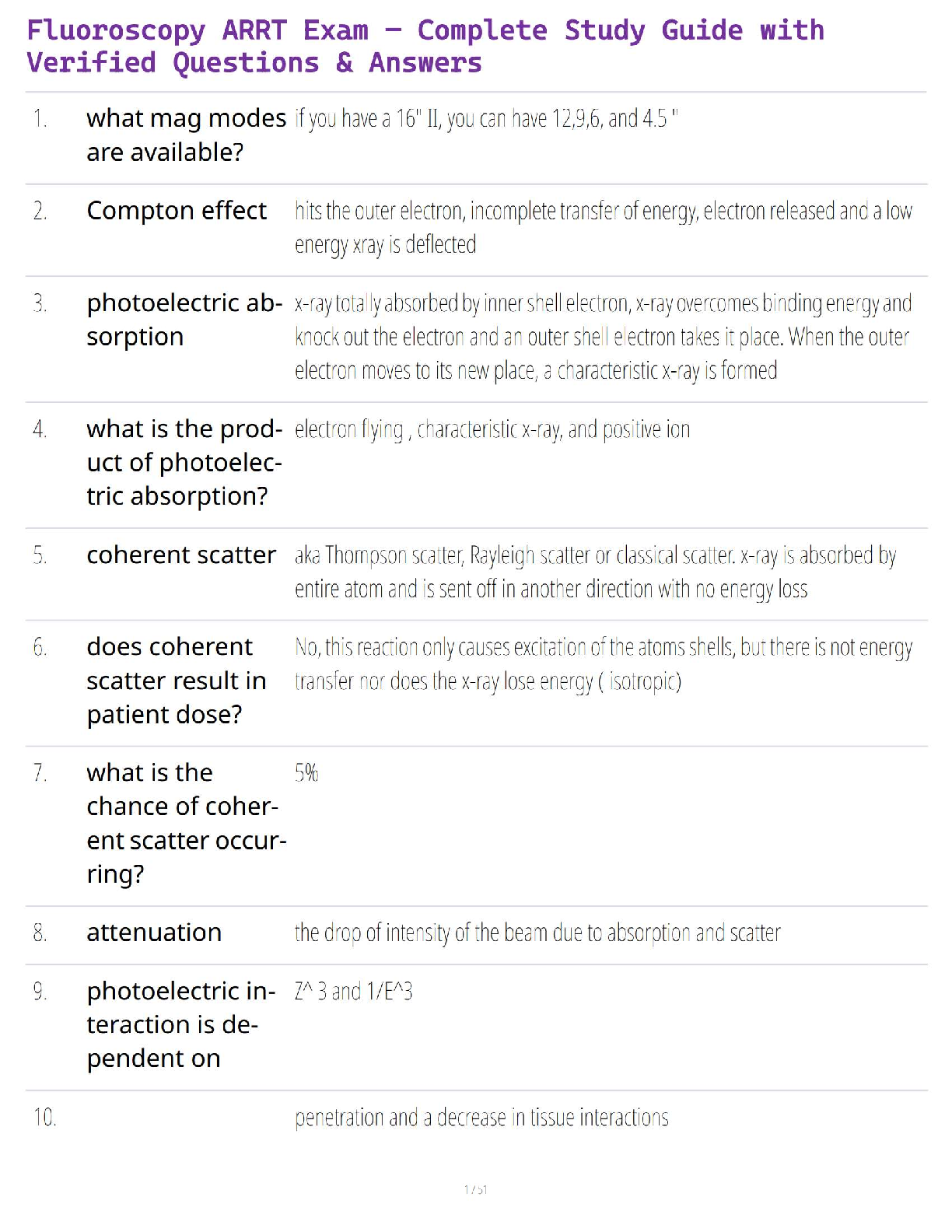

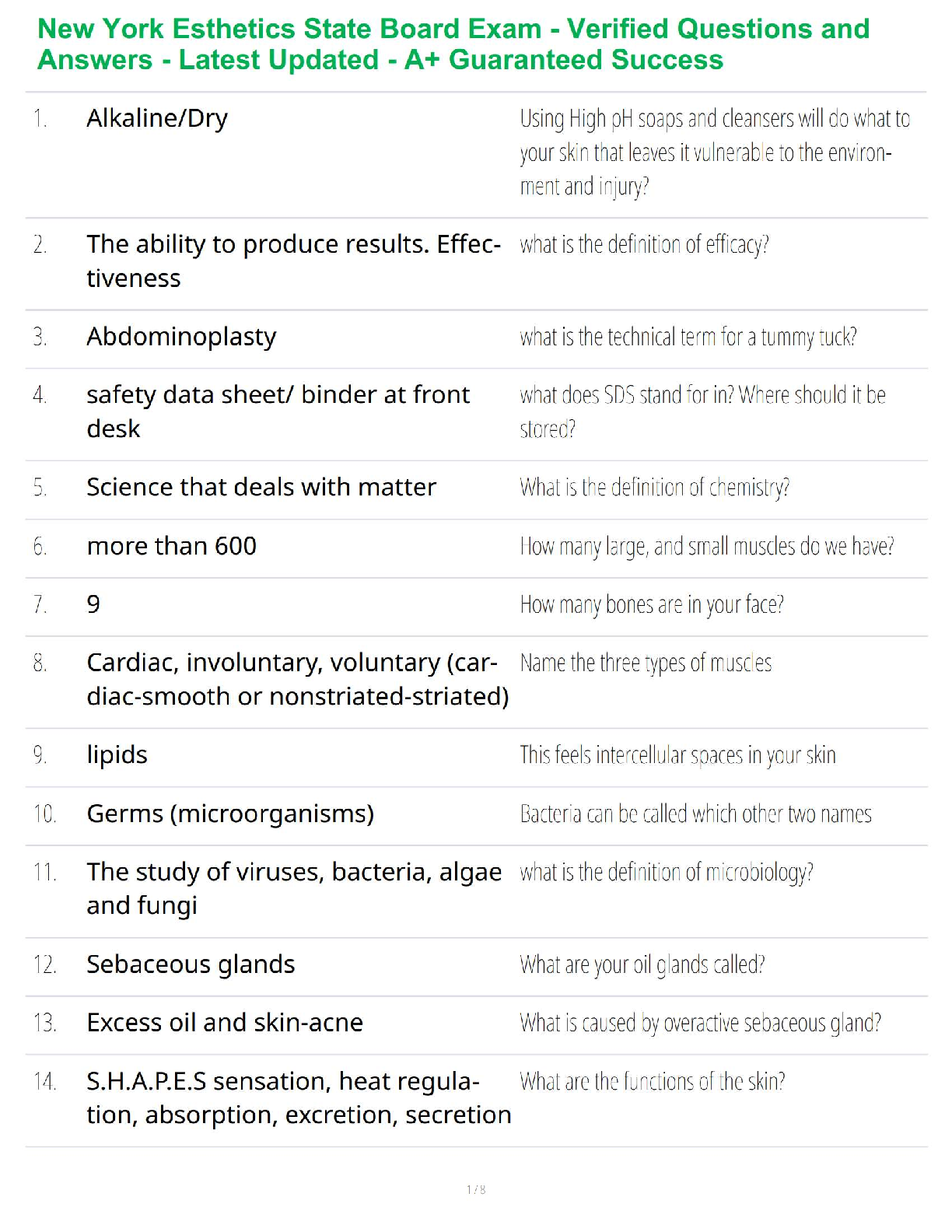

▸ Table 2.1 Characteristics of different scales of production

One-off Small batch Mass or large batch Continuous

Unit cost high medium low low

Tools and equipment general specialised specialised and dedicated dedicated

Initial investment low medium high high

Production efficiency low medium high very high

Labour type skilled skilled and semi-skilled semi-skilled and unskilled unskilled

Labour cost high medium low low

Engineering projects are usually large and complex,

requiring a range of specialist skills to complete. Some of the

great feats of engineering from history, such as Concorde or

the Channel Tunnel, involved tens of thousands of people

working together over decades to bring the project to

fruition. The manufacture of everything, from condensing

boilers to cars, depends on multi-skilled teams of engineers

and technicians working together to manufacture products

quickly, efficiently and in the necessary numbers to satisfy

demand. After manufacture, similar multi-skilled teams are

relied upon to deliver the services that help to maintain and

repair these complex products.

A1 Common engineering processes

Preparation before product manufacture or

product delivery

Generally engineering products or services start life as

ideas on how to solve a particular problem or satisfy some

other demand from a customer or the wider marketplace.

Key terms

Team – a group containing three or more individuals

who have a common objective or shared goal.

Batch – three or more products manufactured or

services delivered together.

Examine common engineering processes to create

products or deliver services safely and effectively

as a team

[Show More]

.png)

.png)