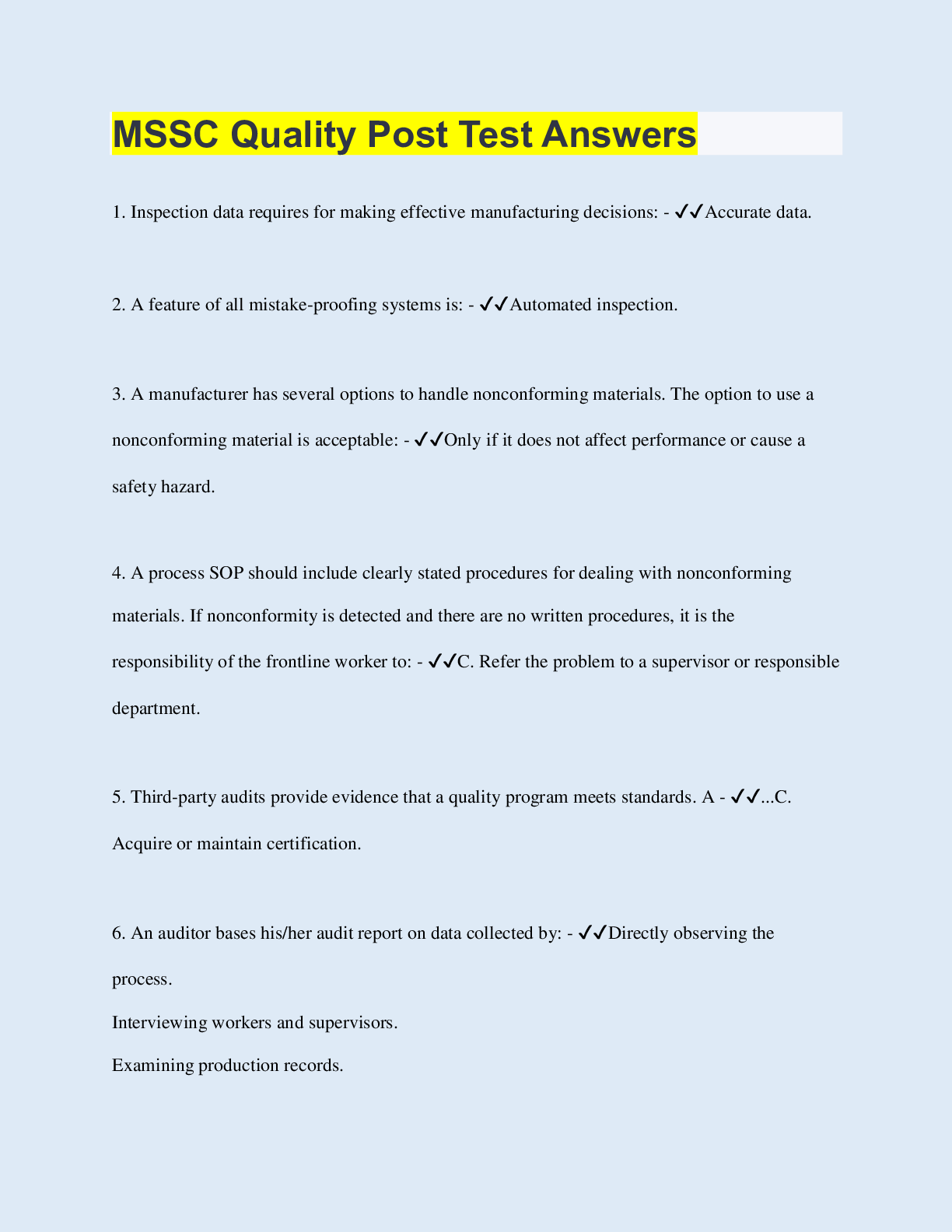

MSSC Quality Post Test Answers

1. Inspection data requires for making effective manufacturing decisions: - ✔✔Accurate data.

2. A feature of all mistake-proofing systems is: - ✔✔Automated inspection.

3. A manufacturer

...

MSSC Quality Post Test Answers

1. Inspection data requires for making effective manufacturing decisions: - ✔✔Accurate data.

2. A feature of all mistake-proofing systems is: - ✔✔Automated inspection.

3. A manufacturer has several options to handle nonconforming materials. The option to use a

nonconforming material is acceptable: - ✔✔Only if it does not affect performance or cause a

safety hazard.

4. A process SOP should include clearly stated procedures for dealing with nonconforming

materials. If nonconformity is detected and there are no written procedures, it is the

responsibility of the frontline worker to: - ✔✔C. Refer the problem to a supervisor or responsible

department.

5. Third-party audits provide evidence that a quality program meets standards. A - ✔✔...C.

Acquire or maintain certification.

6. An auditor bases his/her audit report on data collected by: - ✔✔Directly observing the

process.

Interviewing workers and supervisors.

Examining production records.

7. Inspections can be carried out for several purposes, including as a part of continuous

improvement. To perform inspections, workers should know how to: - ✔✔Read production

documents.

Use inspection and analysis tools

Read safety and environmental standards.

8. A possible source of inaccuracy in inspection data is: - ✔✔Human error.

9. Communication breakdowns can lead to inaccuracies and poor decisions.

Detailed instructions for communicating results must be included in every: - ✔✔Inspection plan.

10. The inspection frequency for any given process depends on a number of factors.

This frequency is specified in a (n): - ✔✔Sampling plan.

11. The main purpose of inspecting the final product is: - ✔✔Product acceptance.

12. Many products require, a record of a material's history. This record is known as

the product's: - ✔✔Traceability.

13. In some cases, nonconforming goods are shipped to a customer if the customer

waives the specification. When this happens, workers should: - ✔✔Be aware that the shipment is

an exception.

14. Many inspections are performed by frontline workers. Quality management

systems require that the company: - ✔✔Provide training of proper procedures for testing.

Include training in health, safety, and environmental procedures.

Keep complete documentation of all training.

15. The purpose of a quality audit is to: - ✔✔Provide assurance that the process follows the

guidelines of the quality plan.

16. The three types of quality audits are: - ✔✔Internal, external, and third-party.

17. An audit report is always presented to the person or organization requesting the

audit. A summary of each discrepancy from standards should also be available to: -

✔✔Production workers involved in the process.

18. What documentation is required for "first piece" inspections? - ✔✔D. In-process form

19. Product testing must include shipping tests to: - ✔✔B. Identify problem areas in product

design or assembly

20. If two angles are complementary, then both are angles. - ✔✔Acute

21. Which of the following is involved with reducing setup? - ✔✔First good piece every time

22. When using a nut, bolt, flat washer, and lock washer, the lock washer should be

positioned: - ✔✔Between the nut and flat washer

23.Which of the following is included in a manufacturing process? - ✔✔Machine resources

24. Dial indicators are adaptable for use with: - ✔✔Snap gauges

25. Arrowheads are used on a drawing in many applications. One of the applications

is lines. - ✔✔Cutting plane

26. Follow-up and closeout of audit-initiated corrective actions is a part of: - ✔✔The audit

function

27. Which of the below organizations is primarily involved in helping companies to

consistently produce high quality products? - ✔✔ISO

28. Upon review of production results, it was determined that 350 out of 5,000 pieces

were "out of spec". What percentage of the production was "out of spec"? - ✔✔7 percent

29. According to specifications, the width of a part is given as 4.253(+0.004). Which

of the following widths would be considered "out of spec"? - ✔✔4.258

30. According to specifications the depth of an aspect of a part is given as 0.523(+1-

0.002) inches. Which of the following would be the most appropriate tool to use in order

to determine if a particular part is in spec? - ✔✔Micrometer

31. Which of the following are determined primarily by the customer? - ✔✔Spec limits

32. A type of graph that shows the frequency of distribution of measured data is a: -

✔✔Histogram

33. A non-conforming product may be shipped to a customer: - ✔✔If the defect does not affect

quality or performance

34. A good quality control system can affect all of the following EXCEPT: - ✔✔B. Cost of raw

materials

35. An important aspect of a process quality audit is that it is conducted by: - ✔✔An independent

party

36. Adjusting a device to a standard is called: - ✔✔Calibration

37. A surface plate is - ✔✔Used as a reference source

38. A is used as the reference part. - ✔✔Gage block

39. What question on a Corrective Action Report (CAR) is used to determine if a

corrective action has taken place? - ✔✔D. What were the results

40. SPC stands for - ✔✔Statistical process control

41. A histogram with bimodal distribution is an indication of - ✔✔Two distinct datasets

42. The chart that will plot the average value of a subgroup is the - ✔✔X Bar

43.Geometric dimensioning and tolerancing refers to - ✔✔limits of size (tolerancing)

44. The "ECN" acronym stands for - ✔✔Engineering change notice

45. A digital caliper would be connected to a PCin order to: - ✔✔D. Collect SPC data

47 Companies use a "quality metric" to: - ✔✔Establish measurements for process improvements

46. Problem analysis tools include - ✔✔Brainstorming

Cause and effect diagrams

Root cause analysis

48. A "third party" audit organization is defined as: - ✔✔D. Someone outside the organization

49. An audit checklist is used to: - ✔✔Obtain relatively uniform results

50. A quality audit is performed in order to - ✔✔Ensure that processes and procedures are

followed

51. X Bar: - ✔✔A chart that will plot the average value of a subgroup

52. Calibration - - ✔✔Adjusting a device to a standard.

53. Histogram - - ✔✔A type of graph that shows the frequency of distribution of measured data.

54. ISO 9000 - - ✔✔A family of international standards that apply to the design and

implementation of quality systems

55. Run Chart - - ✔✔A chart that tracks a measured value over time.

56. PDCA cycle- - ✔✔A simple process for implementing continuous improvement changes in

four steps: plan, do, check, and act.

57. What type of feature is parallel to the surface being dimensioned? - ✔✔Dimension line

58. What part of an assembly fastener is designed to protect the threads _____. - ✔✔Shank

60. One inch is equal to _______. - ✔✔25.4mm

59. Metals treated by ____ processes to become soft. - ✔✔Annealing

61. A _______ is a measurement tool that measures part dimensions by indicating the amount of

distance its probe moves when placed against the part. - ✔✔Dial indicator

62. The due date for calibration must appear on the calibration label of ____. - ✔✔.

Measurement & test equipment.

63. What are the two types of assembly drawings? - ✔✔Detailed and exploded

64. Section lines on a blueprint indicate ______. - ✔✔A surface that has been cut

66. Which of the following is not one of the six rules for the dimensioning an object? - ✔✔.

Dimension hidden lines

65. What type of hole is shown in the picture? - ✔✔b. Counterbore

67. If 200 parts are sampled from 3000 products, what is the sampling rate? - ✔✔6.7 percent

68. Parts are inspected _______ to make sure the typical characteristics of a produced part are

found. - ✔✔Randomly

69. If a sampling plan required 5% of the parts to be inspected in 1000 parts? - ✔✔50

70. How many kg are in 60 pounds? - ✔✔27.3 kg in 60 lbs.

71. If you find the Root cause of a problem what is the next step in the process? - ✔✔Call a

meeting with your quality team

72. Find the length of A - ✔✔25

73. What are you measuring? - ✔✔currents/amps

or I

74. PDCA where does cause and effect diagram be on hand? - ✔✔Plan

75. Histogram Sample - ✔✔This chart reflects normal distribution

76. To eliminate indicator measurement error a device called a _____ is used as a reference part.

- ✔✔C. Gauge block

77. A_____ is the total amount by which specified to dimension is allowed to vary and still be a

good - ✔✔C. Tolerance

78. The dial indicator and makes measurement using the ____ method. - ✔✔A. Indirect

comparison

Production department develop a quality history database by __________. - ✔✔c. Recording

inspection data

80. A ______ is used to determine which type of defect most frequently occurs. Pareto chart -

✔✔Quality of design- Intention of designers to include or exclude features in a product or

service

81. Parts labeled ______ should be inspected to determine if they should be reworked or

scrapped. - ✔✔HOLD

82. DFMEA when performing on existing or new products - ✔✔Do this as early as possible in

the design process.

83. Defects should be reported to - ✔✔The appropriate contact

84. The truck driver delivers a load but does not have the certification for the load what should

you do? - ✔✔D. Place a hold tag and inform purchasing department

85. Stored data reports should be - ✔✔Kept safe stored in a secondary location to prevent loss.

86.Which of the bases for establishing verification intervals. - ✔✔Reliability

[Show More]