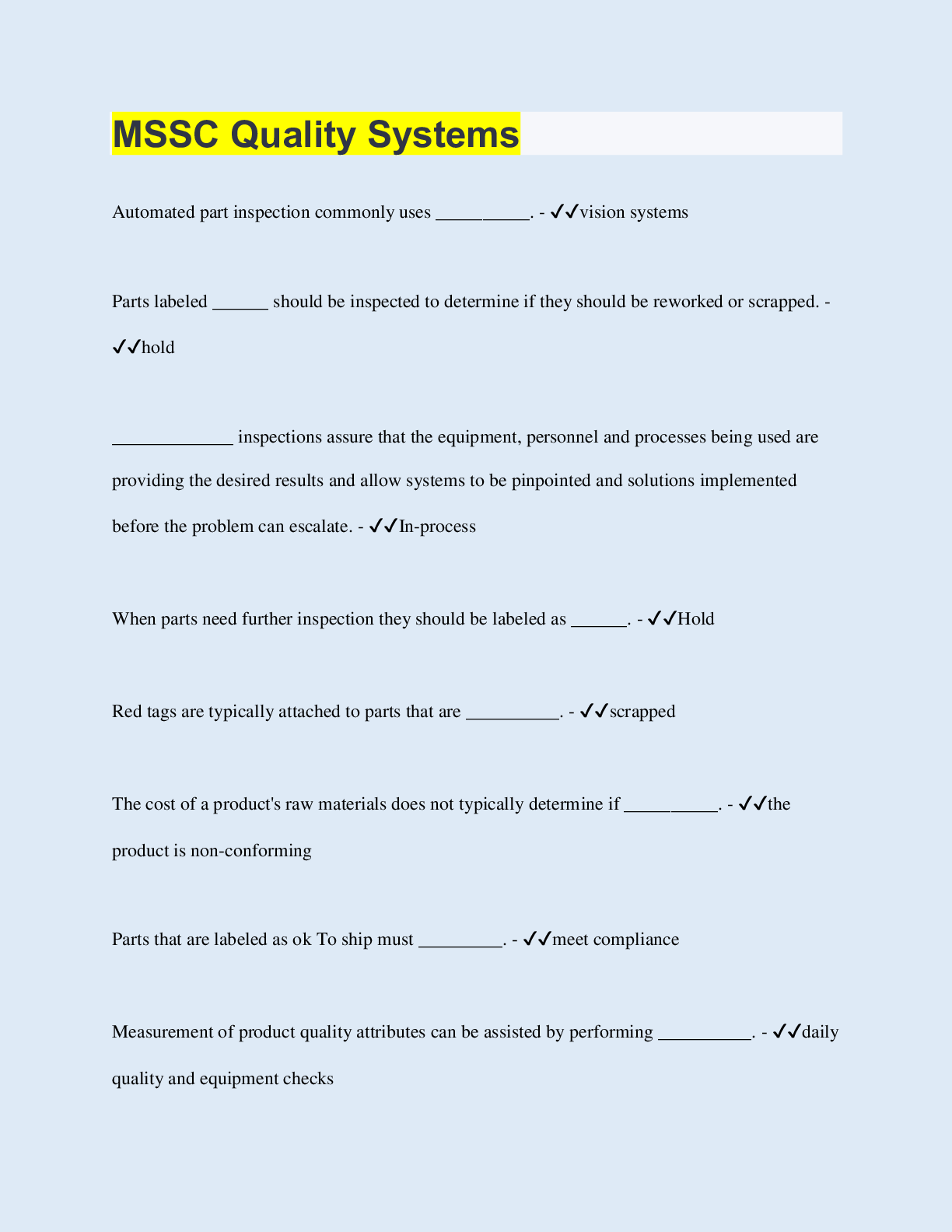

MSSC Quality Systems

Automated part inspection commonly uses __________. - ✔✔vision systems

Parts labeled ______ should be inspected to determine if they should be reworked or scrapped. -

✔✔hold

_____________ inspect

...

MSSC Quality Systems

Automated part inspection commonly uses __________. - ✔✔vision systems

Parts labeled ______ should be inspected to determine if they should be reworked or scrapped. -

✔✔hold

_____________ inspections assure that the equipment, personnel and processes being used are

providing the desired results and allow systems to be pinpointed and solutions implemented

before the problem can escalate. - ✔✔In-process

When parts need further inspection they should be labeled as ______. - ✔✔Hold

Red tags are typically attached to parts that are __________. - ✔✔scrapped

The cost of a product's raw materials does not typically determine if __________. - ✔✔the

product is non-conforming

Parts that are labeled as ok To ship must _________. - ✔✔meet compliance

Measurement of product quality attributes can be assisted by performing __________. - ✔✔daily

quality and equipment checks

The sampling plan uses a(n) _________ chart that indicates to an inspector the number of parts

to inspect based on the size of the product batch. - ✔✔frequency

Certain characteristics of parts are essential for its proper operation. Identifying these

characteristics as _______ helps set up a meaningful quality inspection program. - ✔✔critical

An engineering change notice (ECN) is used to notify changes to __________. - ✔✔a product

drawing

The review of audit procedures and instructions are control and planning functions within a(n)

__________. - ✔✔traceability program

A ___________ is used to verify that the proper procedures and processes are being adhered to

by plant personnel. - ✔✔quality audit program

Instrument reliability is examined to determine _____________________. - ✔✔calibration

intervals

The calibration of instruments and measurement devices is typically checked as a part of a

_______________. - ✔✔quality audit

Machine time, task time, and quality requirements are information needed to __________. -

✔✔document each process

Manufacturers would typically have a _______________ performed to make sure its quality

system is being maintained effectively. - ✔✔quality system audit

A(n) ________ should always be someone outside the organization. - ✔✔third party audit group

Auditors should always _____________ if the problem has been corrected. - ✔✔include the

problem in their report

The main objective of a _____________ is to make sure corrective action is taken to eliminate

problems permanently. - ✔✔Material Review Board (MRB)

Electrical equipment should only be worked on ____________. - ✔✔after someone has

inspected and tested the equipment to ensure that is has been properly de-energized

Results are more uniform if a(n) _____________ is used during an in-process audit. -

✔✔checklist

The quality of the outgoing product can be measured directly with what kind of audit? - ✔✔end

item product

Companies use _________ to show data about the progress of production. - ✔✔job status reports

The principles of ____________ help reduce product costs by managing inventory. - ✔✔Just-intime (JIT)

Machine time, quality requirements, and task time are __________. - ✔✔required to document a

process

Only the supervisor or a person in the quality assurance department can decide if a part on hold

should be __________. - ✔✔scrapped or reworked

A ____________ should be done as often as necessary to assure that processes are sound. -

✔✔quality system audit

Preparing a schedule and a check sheet to ensure that the schedule is followed is part of a(n)

_____________. - ✔✔quality audit management program

To ensure accuracy, __________ are calibrated on a regular basis. - ✔✔inspection tools

Companies typically require that _____________ as a pat of their shop safety rules. - ✔✔safety

glasses be worn

Calibration on which of the following would be audited? - ✔✔Measurement tools

An important requirement in order to achieve Just-in-time manufacturing is to ___________. -

✔✔schedule jobs well

As part of a process of continuous improvement, companies use ________ to set goals for to

strive towards. - ✔✔product benchmarks

The purpose of ISO 9000 is to help companies ___________. - ✔✔improve quality

Employee feedback and data collection are essential elements of an ____________. - ✔✔quality

assurance system

Under the guidelines of _______, manufactures only produce items for inventory stock when

there is a custom order. - ✔✔just-in-time manufacturing

Manufacturers use _________ to avoid use of the wrong material in a process, issuance of the

wrong material from stock and material test failures - ✔✔raw material controls

The number of rejected parts is a reflection on the impact of the _____. - ✔✔quality assurance

system

The __________ organization is an international organization that provides standards for

certification of quality in companies. - ✔✔ISO

Companies typically include policies and procedures for continuous improvement as part of their

______________. - ✔✔quality assurance system

The international standards used for company quality are published by _____________. -

✔✔ISO

The number of defects produced is a measure of _______. - ✔✔The effectiveness of a quality

assurance system

Defect prevention is the _______ of the four types of quality cost - ✔✔most cost effective

It is __________ for workers to inspect and sort out defective products than to prevent defects

from occurring altogether. - ✔✔more costly

Continuous quality improvement programs can _________. - ✔✔increase profits even if sales do

not increase

Increasing customer satisfaction by promoting product reliability can be accomplished by

implementing a _______. - ✔✔quality system

The performance of the product as viewed by the customer is ultimately the most important

measure of ___________. - ✔✔product quality

When the quality of a product improves, it is a sign that _________. - ✔✔continuous

improvement activities are working

A good __________ can both increase value to the customer and reduce product cost. -

✔✔quality assurance system

When less labor is needed to produce the same of more quantity of product, there is __________.

- ✔✔higher productivity

Processes are often described by a ________. - ✔✔sequence of events

An example of a spreadsheet function is __________. - ✔✔SUM

______________ may provide valuable information concerning a product's quality. -

✔✔Performing equipment check during a quality inspection.

New product design teams should perform an _______ as early in the design process as possible.

- ✔✔design failure mode and effect analysis.

Benchmarking is a ________ tool. - ✔✔process improvement

Manufacturing is still in the early stages of study in its effort to find tools to ________ in a

manufacturing process. - ✔✔predict human reliability

Spreadsheets are used to perform calculations in ___________ and produce graphs - ✔✔rows

and columns

The operator is the first person who is responsible for _________ in the production process. -

✔✔product quality

The PDCA cycle was created by W. Edwards Deming and stands for. - ✔✔plan, do, check, and

act

The quality assurance department is the group who provides information to help _______. -

✔✔compare actual quality to customer needs

Production personnel use standard operating procedures to determine ___________. - ✔✔The

proper way to do a task

An important statistic is calculated by dividing the number of parts produced by the number of

hours worked. This stat is called __________. - ✔✔labor productivity

Modern companies emphasize good communications to __________. - ✔✔improve quality

The safety of personnel and the equipment as well as the performance of the equipment are the

key points to keep in mind when making a decision to __________. - ✔✔run to failure or shut

down to fix

Companies often ____________ to create a baseline measurement for improvements in machine

performance - ✔✔establish a metric

A key concept in continuous improvement is to search for ways to eliminate waste in actions,

time, and ______. - ✔✔material

Employees commonly use email to ________ employees at other computers - ✔✔send messages

in text form to

The ___________ should be stored in a safe location after an order is shipped. - ✔✔appropriate

documentation

Reduced costs and increased value are products of _____________. - ✔✔good quality assurance

systems

If current means used to inspect and monitor processes prove to be unsuitable, ____________. -

✔✔they should be corrected using an appropriate procedure

[Show More]