NATE Core Exam Practice Questions and Correct Answers.

$ 14

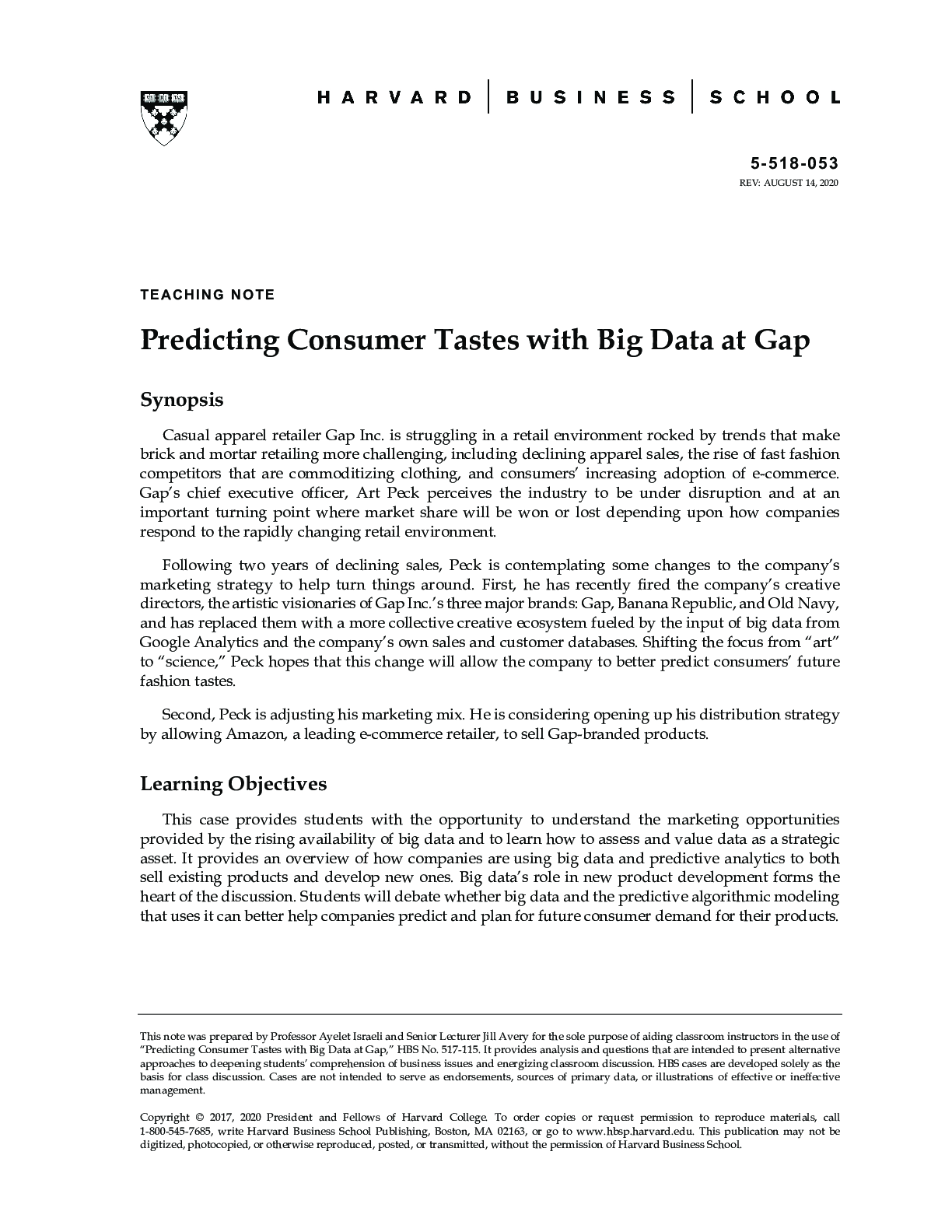

Predicting Consumer Tastes with Big Data at Gap By Ayelet Israeli, Jill Avery (Case Notes Answer with Free Case File)

$ 20

eBook ntertextuality 2.0, Metadiscourse and Meaning-Making in an Online Community,OXFORD STUDIES SOCIOLINGUISTICS SERIES,1st edition by Cynthia Gordon

$ 30

[eBook][PDF]Data Structures and Algorithms in C++, 2nd Edition By Michael T. Goodrich, Roberto Tamassia, David M. Mount

$ 14.5

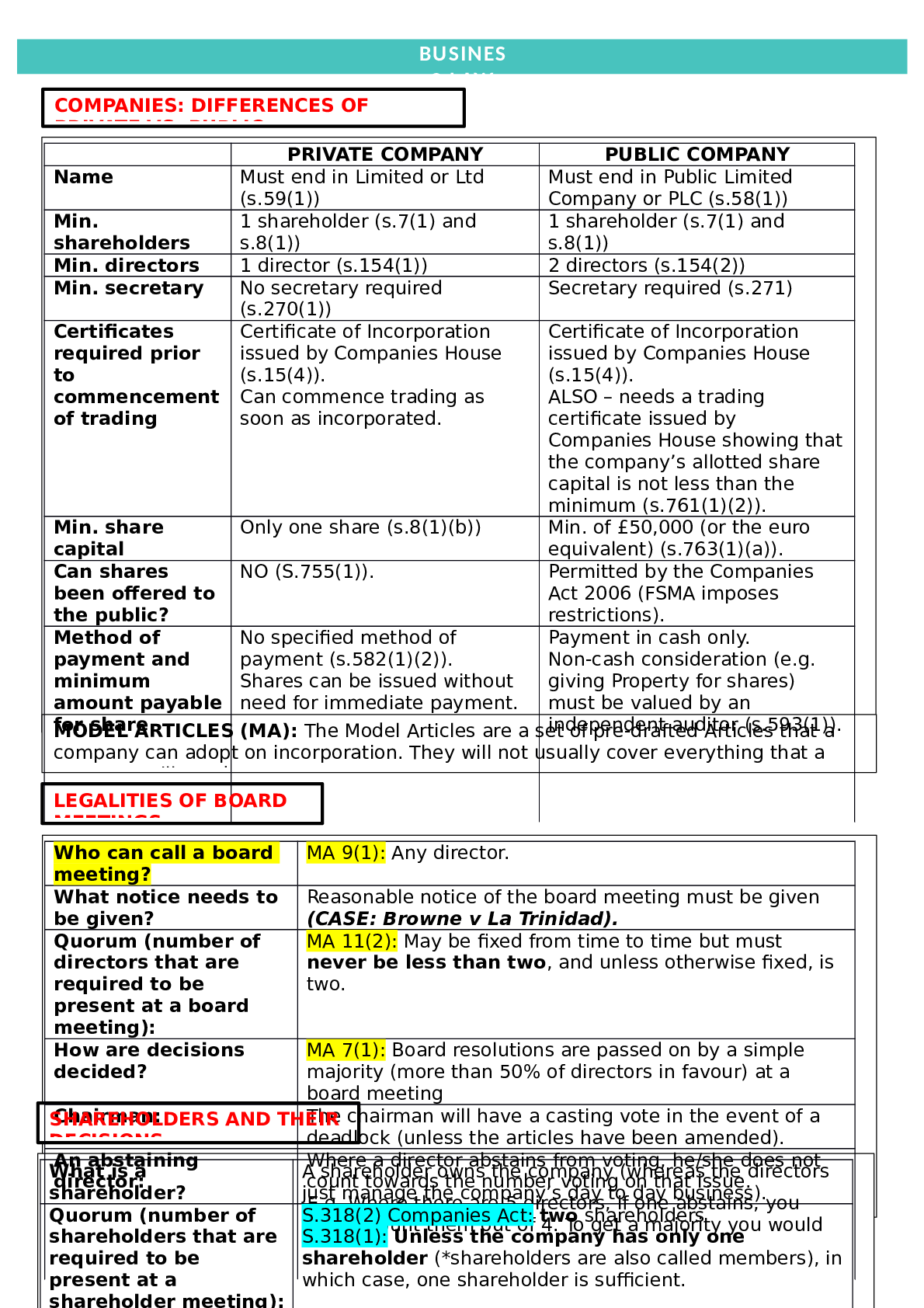

BLP MOCK REVISION NOTES(2021)

$ 16.5

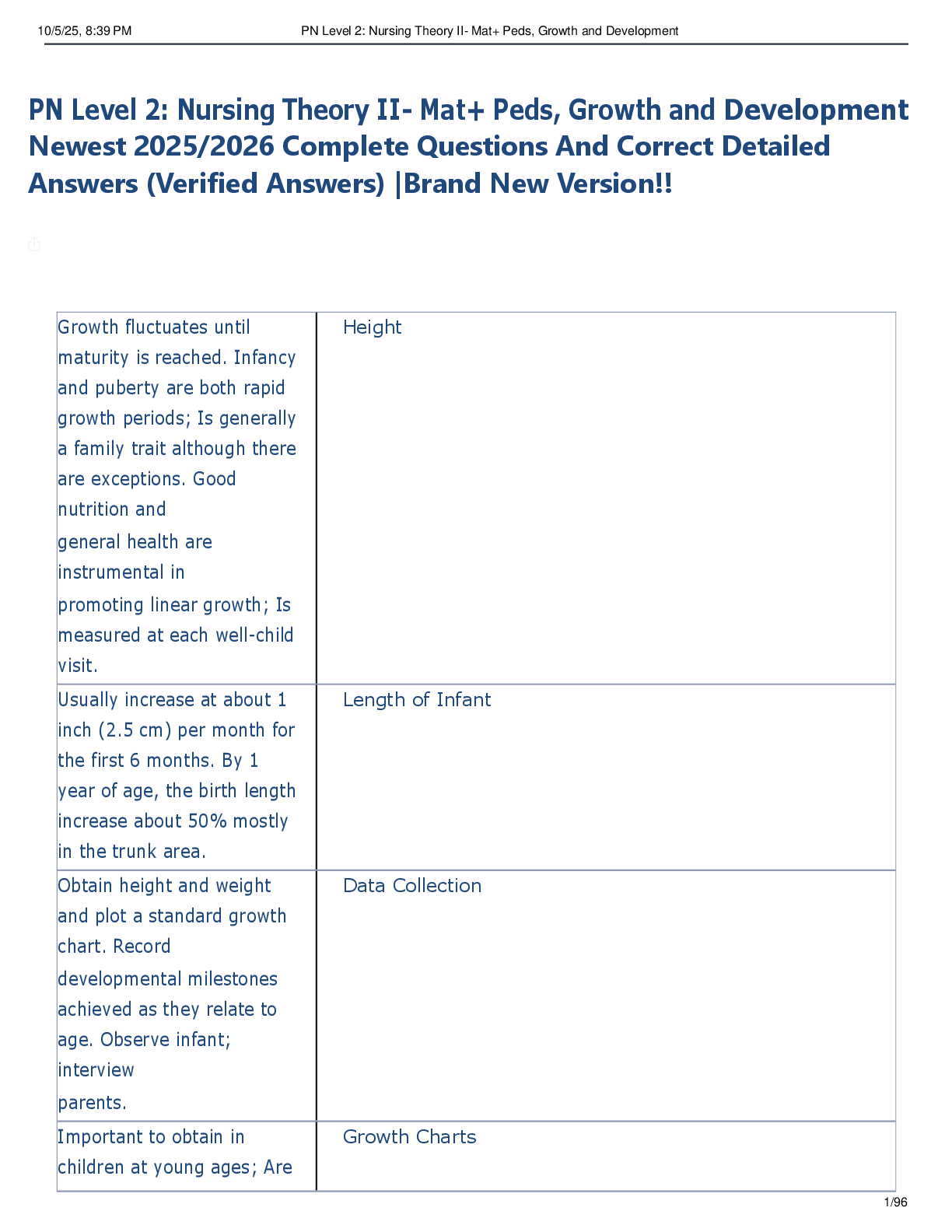

PN Level 2: Nursing Theory II- Mat+ Peds, Growth and Development Newest 2025/2026 Complete Questions And Correct Detailed Answers (Verified Answers) |Brand New Version!!

$ 16

[eTextBook] [PDF] Writing Appalachia An Anthology 1st Edition By The University Press of Kentucky

$ 29

Test Bank for Taylors Clinical Nursing Skills;A Nursing Process Approach 5th Edition by Pamela Lynn - All Chapters included

$ 32

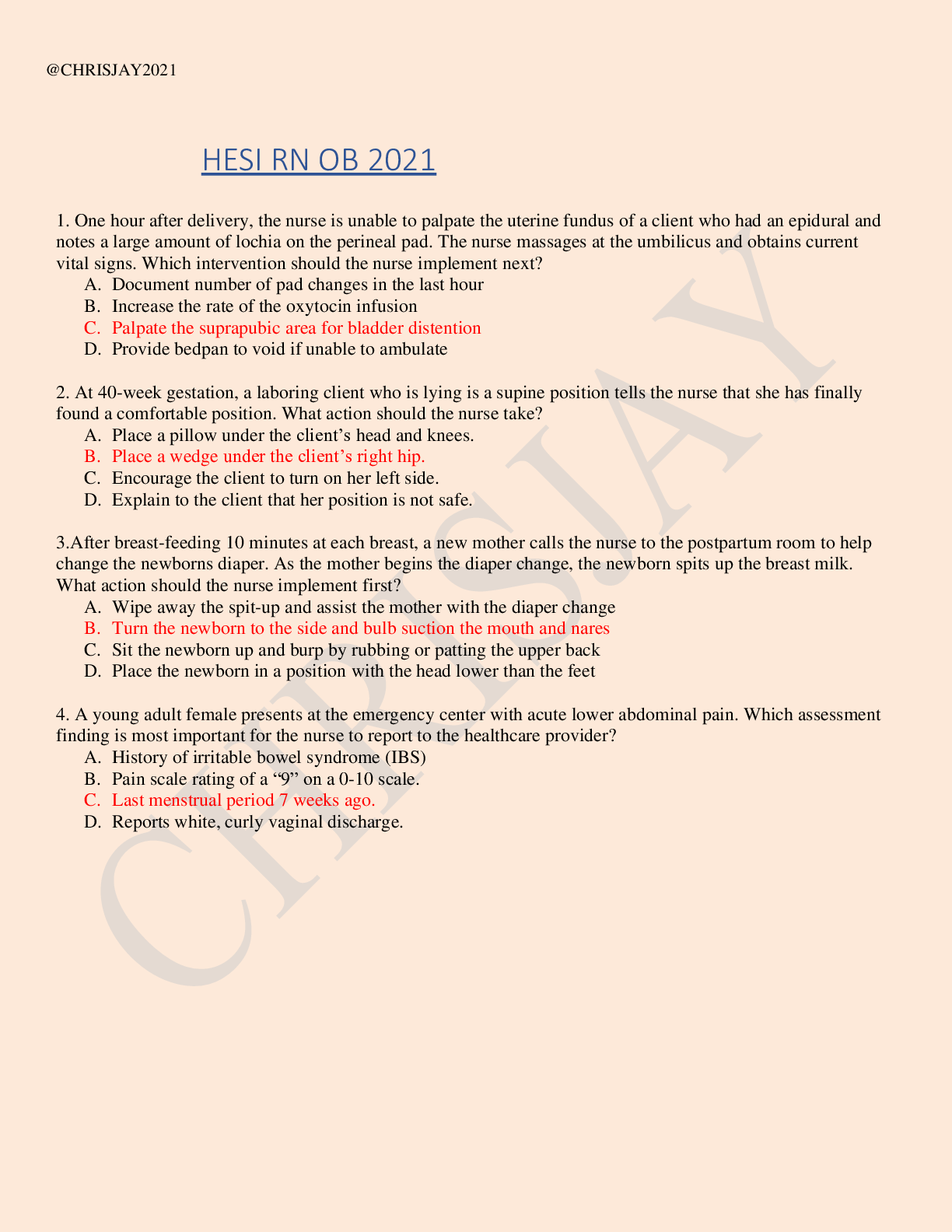

HESI RN OB

$ 20

eBook [PDF] Exploring Communication Theory Making Sense of Us 2nd Edition By Kory Floyd, Paul Schrodt, Larry Erbert, Kristina Scharp

$ 25

eBook Assessing Measurement Invariance for Applied Research 1st Edition By Craig S. Wells

$ 29

APM #1: Application Portfolio Management (APM) CIS Exam ServiceNow

$ 10

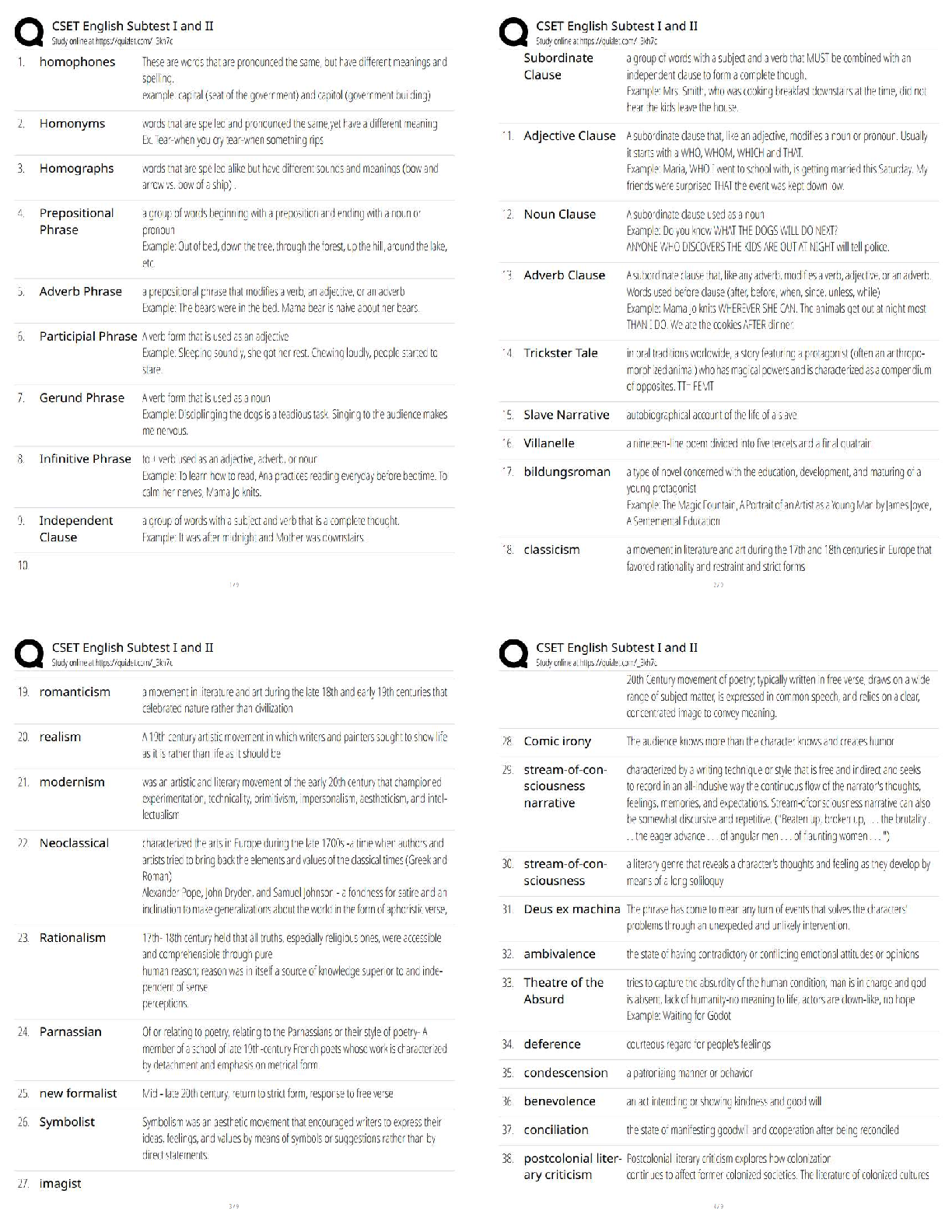

CSET English Subtests I & II Study Guide / 2025 Update / Score 100% Prep