CHAPTER I

DATA COLLECTION AND PROCESSING

1.1 Stopwatch Time Study

Stopwatch time study is a work measurement that was popular and widespread

in 1970s. Many company from automotive, textile, and other manufacturing in

...

CHAPTER I

DATA COLLECTION AND PROCESSING

1.1 Stopwatch Time Study

Stopwatch time study is a work measurement that was popular and widespread

in 1970s. Many company from automotive, textile, and other manufacturing industries

used this method on every production job in a company by developing standard times

based on this study. Stopwatch time study is a type of direct time measurement that

applied to highly repetitive and short-in-time jobs (Wignjosoebroto, 2000). In this

study, time required to perform an operation and environmental condition are

recorded. The principle objectives of stopwatch time study are to increase

productivity, product reliability, and lower unit cost. Thus, allowing more quality

goods or services to be produced for more people. Output of this practicum is the

measurement of standard time to complete an activity that used as a standard time of

work for all workers. Stopwatch time study widely applied in the repeatedly daily

activities that take a short time, such as bolts-nuts installation on a vehicle, assembling

puzzle, and so on.

The advantages of stopwatch time study are the measurement done directly, the

equipment to do this method are quite simple, and the steps to finish stopwatch time

study in order to define work time standard are easier. The disadvantages using

stopwatch time study in work measurement are need more than one operator to do

analyzing work element in stopwatch time study (one person as time keeper, one

person as operator), potentially human error occurred when calculate the time (Rao,

2008).

1.2 Existing Method

This subchapter consists of the existing method from stopwatch time study

practicum.

1.2.1 Departmentalization and Work Flow of Existing Method

Here are the existing methods of departmentalization that shows operations

and activities in each department.

II-1Table 1.1 Department 1 Departmentalization

Department 1: Book Patterns Formation

Operation 1: Draw the book patterns on the flannel

Working element 1: Drawing the book patterns fit in with the size on the first flannel

Allowance

Material Handling

Table 1.2 Department 2 Departmentalization

Department 2: Accessories Patterns Formation

Operation 2: Draw the first accessories patterns on the flannel

Working element 1: Drawing the first accessories patterns fit in with the size on the second

flannel

Operation 3: Draw the second accessories patterns fit in with the size on the third

flannel

Allowance

Material Handling

Table 1.3 Department 3 Departmentalization

Department 3: Book Patterns Cutting

Waiting

Operation 4: Cutting the book patterns on the flannel

Working element 1: Cutting the first flannel fit in with the patterns

Allowance

Material Handling

Table 1.4 Department 4 Departmentalization

Department 4: Accessories Patterns Cutting

Waiting

Operation 5: Cutting the first accessories patterns on the flannel

Working element 1: Cutting the second flannel fit in with the patterns

Operation 6: Cutting the second accessories patterns on the flannel

Working element 2: Cutting the third flannel fit in with the patterns

Table 1.4 Department 4 Departmentalization (con’t)

Department 4: Accessories Patterns Cutting

Operation 7: Cutting satin ribbon

Working element 3: Measuring the satin ribbon fit in with the determined size

Working element 4: Cutting the satin ribbon fit in with the size

Allowance

Material Handling

Table 1.5 Department 5 Departmentalization

Department 5: Assembly

II-2Waiting

Operation 8: Assembling the pieces of book patterns

Working element 1: Assembling all pieces of book patterns

Operator 9: Assembling satin ribbon

Working element 2: Putting satin ribbon on the assembled side

Operator 10: Assembling the book with the accessories

Working element 3: Assembling the first book accessories on the assembled side

Working element 4: Assembling the second book accessories in front of cover

Allowance

Material Handling

Table 1.6 Department 6 Departmentalization

Department 6: Finishing

Waiting

Operator 11: Assembling key chain ring

Working element 1: Estranging key chain ring

Working element 2: Putting key chain ring on the satin ribbon hole

Operation 12: Writing "BOOK" on the cover

Working element 3: Writing the word "BOOK" on the book cover (second book

accessories)

Allowance

Material Handling

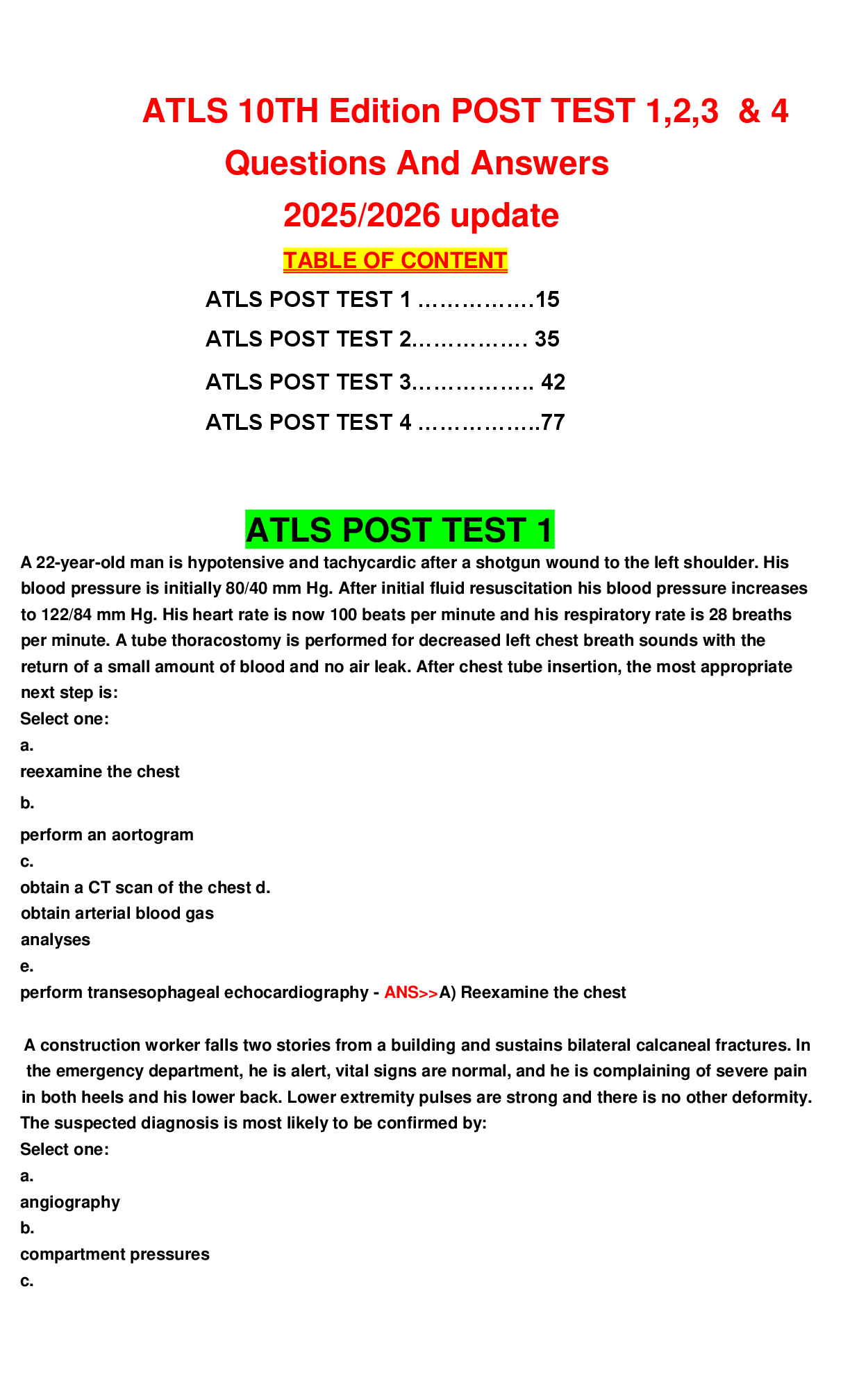

Here is work process of key chain and phone chain department based on

departmentalization before.

Figure 1.1 Work Process of Key Chain Department

1.2.2 Existing Data Recapitulation

Here are data recapitulations of each department’s operation time.

Table 1.7 Department 1 Operation Time Recapitulation

Department 1: Book Patterns

Formation

Working Time of nth Product

X 1 3 4 5 6

II-3Operation 1 : Draw the book pattern on purple flannel

Work element 1 : Drawing the book

patterns that fit in with the size on

purple flannel

47 37 25.9 35 29.4 27.6

Operation 2 : Draw the book pattern on orange flannel

Work element 2 : Drawing the book

patterns that fit in with the size on

orange flannel

26 41 22.2 29 24.1 25.9

Allowance 2 1.3 2.05 0 0 0

Material Handling 7 6.6 6.6 6.7 6.9 6.9

Table 1.7 Department 1 Operation Time Recapitulation (con’t)

Department 1: Book Patterns

Formation

Working Time of nth Product Average

7 9 10 11 12

Operation 1 : Draw the book pattern on purple flannel

Work element 1 : Drawing the book

patterns that fit in with the size on

purple flannel

30 26 21.9 33 29 29.45

Operation 2 : Draw the book pattern on orange flannel

Work element 2 : Drawing the book

patterns that fit in with the size on

orange flannel

24 28 33.7 38 27.1 29.38

Table 1.7 Department 1 Operation Time Recapitulation (con’t)

Department 1: Book Patterns

Formation

Working Time of nth Product Average

7 9 10 11 12

Allowance 0.5 0.3 0 0 0 0.41

Material Handling 6.8 6.8 5.7 6.7 7 6.67

Table 1.8 Department 2 Operation Time Recapitulation

Department 2: Accessories Patterns

Formation

Working Time of nth Product

X 1 3 4 5 6

Operation 3 : Draw the side accessories pattern on green flannel

Work element 1 : Drawing the patterns

that fit in with the size on green

flannel

23 17 28.5 26 29.4 34.5

Table 1.8 Department 2 Operation Time Recapitulation (con’t)

Department 2: Accessories Patterns

Formation

Working Time of nth Product

X 1 3 4 5 6

Operation 4 : Draw the front accessories pattern on green flannel

[Show More]

.png)